Styrene-Butadiene Rubber

Styrene-Butadiene Rubber

WHAT IS STYRENE BUTADIENE RUBBER?

Styrene-Butadiene Rubber – SBR is produced by a technology of cold emulsion copolymerization based on soaps of rosin and fatty acids. It contains 23.5% of chemically bonded styrene, and is coagulated by a system of acid and synthetic coagulant. SBR has superior properties such as process ability, abrasion resistance, and less tendency in scorching processing. More than half of the world E-SBR production is principally used in Manufacturing tires.

SBR rubber does not crystallize when stretched like natural rubber, and therefore is weak unless reinforced with carbon black or other materials. Even so, it is weaker than natural rubber. Its volcanic properties are good and its aging characteristics are satisfactory. More than 70% of produced SBR is consumed in tire tread, 15% in mechanical parts and about 10% in the form of leachate. Styrene Butadiene Rubber (SBR) is widely preferred in many industries today and also called as the world’s only synthetic rubber. SBR, as the chemical substance, is a mixture of approximately 75% butadiene and 25% styrene. Styrene-Butadiene Rubber – SBR, which is a general purpose synthetic rubber type, is used much more than other synthetic rubbers. It is used in the production of tires for the trucks and automobile by replacing rubber which is resistant to abrasion. Most of the synthetic rubbers produced worldwide are made of styrene-butadiene rubber. Styrene-butadiene rubber, which contains 23% styrene, becomes harder as this ratio increases and the high resistance to low temperature diminishes. Styrene-butadiene rubber, similar to natural rubber, has high ozone and atmospheric durability. The temperature range of the styrene-butadiene rubber varies between 50 and 110 °C. The styrene-butadiene rubber, which is irregular in its structure, provides an economic advantage because the rubber is inexpensive. Our products are available in non-oil or oil extended grades, with non-staining antioxidant.

NON-OIL EXTENDED STYRENE BUTADIENE RUBBER

Grades

Mooney Viscosity

(ML1+4@100°C)

Bounded Styrene (%)

Stain

Application

1500 46-58

23.5 NS Automobile tires, conveyor belts, footwear, cables, hosepipes and various technical rubber goods.

1502 46-58

23.5 NS Automobile tires, floor convering, bicycle tires, footwear, children toys, cables rubber pipes and various rubber goods having light color shades.

1507 30-40

23.5 NS Sponge, industrial goods, rubberized fabric, toys and black products requiring good process ability

OIL EXTENDED STYRENE BUTADIENE RUBBER

Grades

Mooney Viscosity

(ML 1+4@100°C)

Bounded

Styrene (%)

(phr)

Stain

Application

1712 42-52 23.5 NS Automobile tires, conveyor belts, footwear, cables, hosepipes and various technical rubber goods.

1705 46-56 37.5 NS Automobile tires, conveyor belts, footwear, cables, hosepipes and various technical rubber goods.

1721 50-60 37.5 NS Automobile tires, conveyor belts, footwear, cables, hosepipes and various technical rubber goods.

1723 42-52 37.5 NS Automobile tires, conveyor belts, footwear, cables, hosepipes and various technical rubber goods.

FEATURES OF SBR IGNITION

- It burns in the flame and continues to burn after removing the flame.

- The flame is yellow with orange and it makes a little noise.

- It has grayish white smoke with carbon particles.

- SBR does not drip in the flame.

- SBR smells like city gas.

PROPERTIES OF SBR

has excellent erosion resistance, and the more cis and vinyl butadiene are combined in it, the more the erosion resistance of SBR increases, resistance to wear, good bounce, flexibility at low temperature, resistance to cracking. Heat resistance and impact resistance. are among its other features.

ADVANTAGES AND USES

SBR Usage

SBR Usage

The most important advantages that increase the use of styrene butadiene rubber are the economic advantage and durability. In addition, the Styrene-Butadiene Rubber – SBR is extremely resistant to bases, glycol-based brake fluids, and alcohol. The basic uses of styrene butadiene rubber, which also prevents crystallization, are as follows:

- Production of automobile tires

- Shoe manufacturing

- Washbasin seals

- Electric industry

- Sports equipment

- Washing machine rolls

DISADVANTAGES OF SBR

SBR Usage

SBR Usage

- Low resistance to ozone

- Low resistance to flame and ignition

- Very difficult to process

- Low resistance to gasoline and oil

- Low resistance to hydrocarbon solvents

PRODUCTION HISTORY OF SBR

In general, the copolymer of styrene and butadiene (the amount of butadiene must be more than 50%) is called SBR. The normal ratio of monomers is 70% to 75% butadiene to 25% to 30% styrene. If SBR exceeds 50%, the product becomes plastic and is used in latex production.

SBR has many functions and because the raw materials for its production are very available and also has a low price, it has taken a large volume of production in the rubber industry and is one of the most widely used and used tires. is counted

Styrene butadiene rubber was developed and developed in Germany before World War II, and during World War II it was widely used to replace natural rubber in the united states and Germany.

The mechanical properties of SBR are lower than NR and, like it, it does not crystallize due to stretching, and therefore it is weak unless it is reinforced with carbon black or other materials, and even then it is weaker than natural rubber.

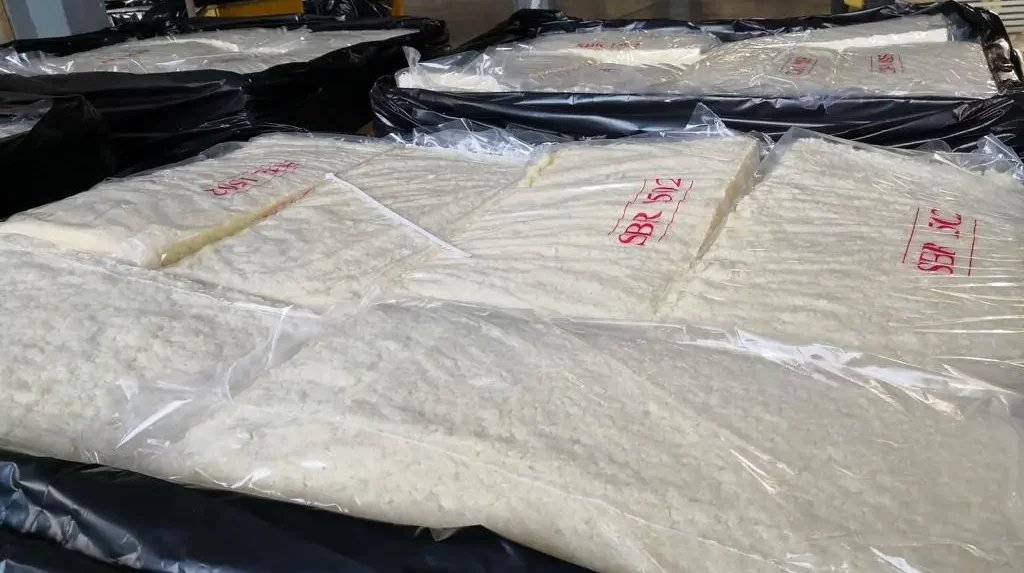

PACKING OF STYRENE-BUTADIENE RUBBER

Solid SBR is commonly packaged in 25-35 kg bales, each wrapped in a durable, moisture-resistant material like polyethylene to safeguard the rubber from contamination and degradation. These bales are then stacked on pallets and securely fastened for transport.

For latex SBR, the material is typically stored in 200-liter drums made of either metal or plastic, with airtight seals to prevent contamination and drying.

Depending on the application, SBR can also be packaged in alternative forms, such as SBR crumb rubber, which is often packed in bags or bulk containers for easier handling and transport.

- 35 ±0.5 KG Bales Wrapped with Polyethylene film

- 36 Bales per Crate (1260±18 KG)

TECHNICAL DATA SHEET OF STYRENE-BUTADIENE RUBBER

Item Unit Specification Result Test Method

Raw Mooney Viscosity MU 42-52 47 ASTM D1646-07

Volatile Matter Content % Max 0.75 0.5 ASTM D5668-09

Ash Content % Max 1.00 0.19 ASTM D5667-95

Soap Content % Max. 0.50 0.15 ASTM D5774-95

Organic Acid % 3.9 - 5.70 4.9 ASTM D5774-95

Bound Styrene % 22.5 - 24.5 23.5 ASTM D5775-95

Compound Properties (ASTM D 1646-03) - ( ML 1+4@ 100° C)1

Compound Mooney

ViscosityMU Max 62 58 ASTM D1646-07

Tensile Strength,

35 min at 145° C curedkg/cm² min 200 235 ASTM D412-06

Elongation at Break,

35 min at 145°C cured% min 530 617 ASTM D412-06

300% Modulus,

35 min at 145°C curedkg/cm² 79 - 109 87 ASTM D412-06

For more information, please Contact our Sales Team.