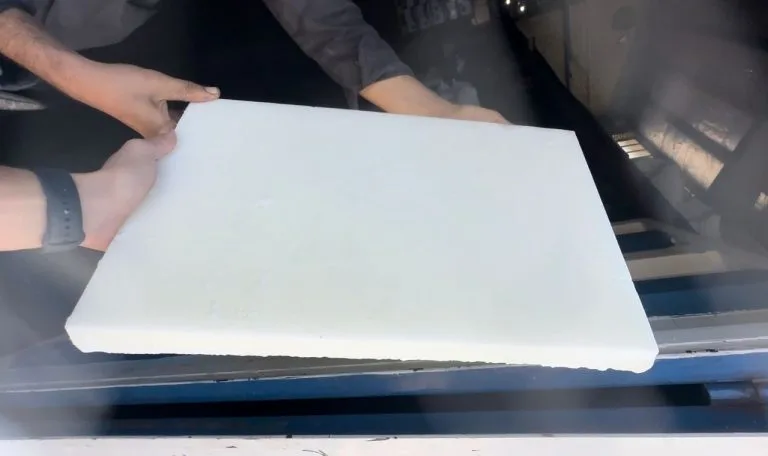

Semi Refined Paraffin Wax Description

Semi-refined paraffin wax is a type of wax derived from crude oil during the refining process. It undergoes partial refinement, leaving some impurities in the wax called slack wax. This wax is often used in various industries, including candle making, packaging, and cosmetics. Its semi-refined state allows for a balance between purity and cost-effectiveness in applications where high levels of refinement may not be necessary.

Paraffin Wax Application

It has diverse applications across several industries:

- Candle Making: It’s commonly used in candle production, providing a cost-effective yet functional material for candle formulation.

- Packaging: In the packaging industry, it’s utilized for coating and sealing purposes due to its moisture-resistant properties.

- Cosmetics: Found in various cosmetic products like creams, lotions, and lipsticks, where it contributes to texture, consistency, and moisture retention.

- Rubber and Tire Industry: Used as a softening agent and processing aid in the manufacturing of rubber and tires.

- Textile Industry: Employed as a sizing agent for textiles, contributing to fabric stiffness and smoothness.

- Pharmaceuticals: It’s used in certain pharmaceutical applications, such as coating pills to control the release of active ingredients.

- Wood and Plywood Industry: Applied as a coating agent in the wood and plywood industry for its water-resistant qualities.

- Electrical Industry: Used for insulation purposes in electrical cables and wires.

- Paper Industry: Applied as a coating or impregnating agent in paper production for improved water resistance.

- Leather Processing: Used in leather processing to enhance texture and water resistance.

Production Proccese

The production process of semi refined paraffin wax involves several steps:

- Crude Oil Extraction:The process starts with the extraction of crude oil from underground reservoirs.

- Refining: Crude oil undergoes a refining process to separate different hydrocarbon fractions. This can include distillation and other refining techniques.

- Dewaxing: The refined oil is then subjected to a process called dewaxing, where it is cooled to precipitate out waxy substances.

- Solvent Deoiling: To further remove impurities, the wax obtained from dewaxing may undergo solvent deoiling. This involves using solvents to extract unwanted components.

- Hydrofinishing: Hydrofinishing is a step to improve the color and odor of the wax. It involves the use of hydrogen under specific conditions to remove impurities.

- Filtering and Packaging: The wax is filtered to remove any remaining solid particles or impurities. After this, it is typically packaged for distribution and use.

The semi-refined paraffin wax obtained from these processes retains some impurities, distinguishing it from fully refined paraffin wax. This level of refinement makes it suitable for various industrial applications where the presence of certain impurities is acceptable or even desirable. It’s important to note that specific production methods may vary between manufacturers, and the quality of the final product can depend on the raw materials used and the refining techniques applied.

Specification of Semi Refined

Specifications for semi-refined paraffin wax can vary based on the intended application and manufacturer. It’s important to note that these specifications can vary between manufacturers and may be tailored to meet the specific needs of different industries and applications. However, here are some general specifications that are commonly considered:

- Color: The color can range from white to various shades of yellow, and even brown. Different industries may have specific requirements for color purity.

- Melting Point: The melting point is a crucial parameter and is often specified within a certain temperature range. Different grades may have distinct melting points to meet specific application needs.

- Oil Content: The oil content in semi-refined paraffin wax can vary. It’s typically expressed as a percentage and is an important factor in determining the wax’s properties, such as hardness and flexibility.

- Penetration: Penetration is a measure of the hardness of the wax and is determined by the depth to which a standard needle penetrates the wax under specific conditions.

- Viscosity: In some applications, viscosity is an important specification, especially in industries like cosmetics where the wax may be used in liquid formulations.

- Impurities: The level of impurities, such as sulfur and other contaminants, may be specified. Lower levels of impurities are often desirable, especially in applications where purity is critical.

- Packaging: Specifications may also include details about packaging, such as the form in which the wax is supplied (slabs, pellets, etc.) and the type of packaging materials used.

Semi Refined of Grades

Semi-refined paraffin wax comes in different grades based on its characteristics, such as color, melting point, oil content and purity. Some common grades include:

- Low Melting Point Grade: This type has a lower melting point and is often used in applications where a softer wax is required, such as in the production of certain types of candles.

- Medium Melting Point Grade: This grade strikes a balance between hardness and malleability. It finds use in various applications, including candles, packaging, and cosmetics.

- High Melting Point Grade: This grade has a higher melting point, making it suitable for applications where a harder wax is needed, such as in the manufacturing of certain types of coatings and industrial products.

- White or Light-Colored Grade: This grade is characterized by its lighter color, making it desirable for applications where color purity is important, such as in the cosmetics and pharmaceutical industries.

- General-Purpose Grade: A versatile grade used in a range of applications, offering a balance between various properties like color, melting point, and cost.

Semi refined paraffin wax grades based on oil content

- Semi Refined paraffin wax with 1-2% Oil content

- Semi Refined paraffin wax with 3-5% Oil content

- Semi Refined paraffin wax with 5-8% Oil content

Semi Refined Paraffin Wax Supplier

RAHA GROUP is manufacturer and supplier of the paraffin wax different grades. Some of destinations we are exporting to is Turkey, Romania, Bulgaria, Serbia, Ukraine, Bosnia, Poland, Greece, Oman, Iraq, Pakistan, India, Taiwan, Thailand, and Vietnam. The quality of cargo guaranteed by our laboratory and SGS or Geo Chem inspection.

Our team will assist at every step to ensure a smooth and timely supply. (Contact Us)