Performance Grade (PG) 76-16

Performance Grade (PG) 76-16

GENERAL DESCRIPTION OF PG BITUMEN

Before knowing about PG 76-16 we should know that the viscosity and penetration based grading systems proven to be inadequate, the strategic Highway Research Program (SHRP) in the US launched a Project between 1987 and 1993 to overcome the flaws in empirical systems.

One of the outcomes of this project was a performance-based binder specification employing a new set of tests. Performance Grade (PG) Bitumen is bitumen is graded based on its performance indicated in different temperatures. In Super pave grading system, according to their performance in extreme hot and cold temperatures, binders are classified and are called as performance grade (PG) bitumen. The main goal of grading asphalt binder using the PG system and selecting it is to make sure that the binder has the appropriate properties needed for environmental situation it’s going to be used in. PG asphalt binders are selected to suit the expected climatic conditions as well as volume adjustments and traffic speed. Therefore, the PG system uses a set of tests to measure physical properties of the binder which can be directly related to field performance in the paving situation.

The Long-Term Pavement Performance (LTPP) has given a controlled algorithm to calculate and derive the temperature of the pavement based on the temperature of the air above. From this, the range of the temperatures of the pavement are indicated and the bitumen that performs the best in the defined conditions is selected. Penetration grading and viscosity grading face some limitations in their ability to completely characterize asphalt binder for use in Hot Mix Asphalt (HMA) pavement. Therefore, as part of the Superpave research, new specifications and binder tests were developed to more accurately and comprehensively to determine the characteristics of asphalt binders to be used in HMA pavements. These tests and specifications are mostly designed to address HMA pavement performance parameters such as fatigue cracking, rutting ,and thermal cracking. Superpave performance Grade (PG) Bitumen is developed on the idea that an HMA asphalt binder’s properties should be according to the conditions under which it is applied. For asphalt binders for instance, this includes expected climatic conditions along with aging considerations. Therefore, the PG system uses a common set of tests (similar to the ones used in penetration and viscosity grading systems) but also determines that a particular asphalt binder must pass these tests at specific temperatures that are a variant based on the specific climatic conditions in the area of application. Although the concept is not new, but the relationships established between asphalt binder properties and conditions of application are more comprehensive and more precise with the Superpave PG system.

PERFORMANCE GRADE BITUMEN 76-16

Performance Grade Bitumen PG 76-16 is graded based on pavement temperatures. In Super-pave grading system, binders are classified according to their Performance in extreme hot and cold temperatures and called as Performance Grade Bitumen. The main purpose of grading and selecting asphalt binder using the Performance Grade system is to make certain that the binder has the appropriate properties for environmental conditions in the field. Performance Grade asphalt binders are selected to meet expected climatic conditions as well as traffic speed and volume

adjustments. Therefore, the Performance Grade system uses a common set of tests to measure physical properties of the binder that can be directly related to field performance of the pavement at its service temperatures by engineering principles. Performance grade bitumen generally are mostly applied in paving constructions and reconstructions, sealing of edges, crack sealing, spray applications for the bridge deck, and in both dense-graded and open-graded Hot Mix Asphalt (HMA). PG grades that are well-structured against thermal cracking are PG 58-34, PG 64-22, PG 64-28, and PG 76-22. PG grades that are resistant to rutting are PG 70-22, PG 70-28, PG 76-28, and PG 82-22.PG 58-28 is specifically used in very cold regions.

WHAT IS POLYMER MODIFIED BITUMEN (PMB)?

PG Asphalt Cement / Polymer Modified Bitumen is a type of asphalt cement designed to offer superior performance and durability compared to conventional asphalt. Styrene-based elastomeric polymers are incorporated into the asphalt cement to create reliable, high-quality products that can resist deformation, aging and water penetration. These modifications provide a higher ionic surface activity, increasing the cohesion between aggregates and the asphalt. With modified bitumen, you also get greater fatigue resistance and enhanced protection from thermal cracking due to high temperatures or temperature variations.

The range of configurations available with PG Modified Bitumen includes Styrene-Butadiene-Styrene (SBS), Styrene-Butadiene (SB), Styrene-Ethylene Styrene Blocks (SEBS), Styrene-Sprene-Styrene (SIS), Radial and Linear SBS, Ethylene Vinyl Acetate (EVA), Ethylene Copolymer Resins (ECR) among others. Each project will require a thoughtful blend of these components creating an asphalt cement that works for that specific application.

Overall, PG (Performance Grade) Modified Bitumen provides powerful advantages over standard asphalt cements in terms of deliverability, longevity and performance in everyday applications.

ADVANTAGES OF PERFORMANCE GRADE BITUMEN

- Empirical methods such as viscosity and penetration grading systems were developed based on old experiences and can be applicable if those conditions still exist. But, climatic and current traffic conditions are rapidly changing and past experiences can no longer be defining criteria. In the PG system, it is possible to use actual traffic volume and vehicle speed which represents the duration of loads are applied.

- Common tests are conducted at a single test temperature which is 25°C in penetration and 60°C in viscosity test, which means that they cannot give any details about how the bitumen would behave in low or high temperatures. Superpave grading indicates a working temperature range of binder and therefore, helps with choosing the best type according to the condition each project demands.

- Because of the visco-elastic properties of bitumen, the rate of load application and temperature have a great effect on its behavior.

- Although the behavior of bitumen in lower loading rates corresponds to that of higher temperatures, none of the other grading systems doesn’t take the rate of load into account except for Superpave.

- While Superpave can be easily used for both unmodified and modified bitumen, conventional methods are used only for unmodified bitumen types,

- Conventional methods ignore the long-term aging of binders and its behavior. But Superpave takes both longterm aging -using with the pressure aging vessel (PAV)- and short-term aging using the rolling thin film oven test (RTFOT)- into account.

- Bitumen properties indicated at different temperatures contribute to resistance to the distresses in a different level. Bitumen contributing in a better rutting resistance is measured at maximum pavement temperatures and which leads to a more elastic and stiffer binder. Bitumen contributing to fatigue resistance is the most crucial at average pavement temperatures and it requires a softer bitumen while it still favors an elastic binder. Bitumen contribution to thermal cracking is sensitive at minimum pavement temperatures and it demands a less elastic and soft bitumen.

SUPERPAVE PERFORMANCE GRADING USES THE FOLLOWING ASPHALT BINDER TESTS:

- Rolling thin film oven (RTFO)

- Pressure aging vessel (PAV)

- Rotational viscometer (RV)

- Dynamic shear rheometer (DSR)

- Bending beam rheometer (BBR)

- Direct tension tester (DTT)

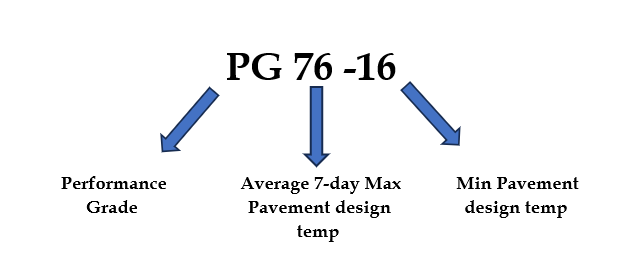

PERFORMANCE GRADE (PG 76-16) BITUMEN NOMENCLATURE

Performance Grade (PG) bitumen is categorized based on traffic and pavement temperature. Modification and monitoring done here, are meant to simulate conditions and traffic volumes to enable us to longer the life span of the pavement and enhance the quality. The PG grading system is defined by two numbers, representing the pavement temperatures. The first number (ex: PG 64-XX) represents the highest pavement temperature in Celsius, while the second number (ex: PG XX-22) represents the lowest. Note that these numbers are pavement temperatures, not the air temperatures (these pavement temperatures are derived from air temperatures using an algorithm included in the LTPP Bind program). The high temperature is related to the effects of rutting and the low temperature relates to cold results such as fatigue cracking.

Grading System PG 76-16

Grading System PG 76-16

Performance Grading Should consider the actual conditions of different paving projects, since it’s dominantly used for paving, such as strain relationship under the field load, traffic speed and volume and the pavement structure.

APPLICATION OF PERFORMANCE GRADE (PG) BITUMEN

PG52-28: is dominantly used in paving for both new construction and road care and also in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing cracks in paving and also the edges. Other applications include spraying in places like bridge deck and pavement protective membrane with fabrics.

PG58-22: is initially used in paving for both dense-graded and open graded Hot Mix Asphalt (HMA) and also in road construction usages as well as spraying and crack sealing applications.

PG58-28: is initially used in paving for both dense-graded and open graded Hot Mix Asphalt (HMA) and also in road construction usages as well as spraying and crack sealing applications. This grade is widely used in very cold areas.

PG58-34: is generally used in the higher elevation roadways. This grade is a paving asphalt cement dominantly used for the production of Hot Mix Asphalt (HMA). It could also be used for sealing the edges of new to old paving and cracks sealing.

PG58-40: is primarily used on the high elevation locations. This grade is paving asphalt for the production of Hot Mix Asphalt (HMA). It can be easily used for sealing purposes and crack treating as well.

PG64-22: is mostly used in paving for both new construction and pavement treatment projects and in both dense-graded and open graded Hot Mix Asphalt (HMA) as well as others. It can be easily used for sealing purposes and crack treating too. Other uses include spray applications for bridge decks and pavement protective layer with fabrics and some modifications. It has been reported that with proper aggregate selections and asphalt content, HMA with PG64-22 as the binder may show less tenderness compared to a similar mixture with a lower viscosity/softer asphalt. This will lead to a significant reduction of typical tenderness problems of mixture shoving and checking during pavement surface scuffing and rolling and markings caused by traffic immediately after paving.

PG64-28: is primarily used in road construction and paving for new and pave care projects and in both dense-graded and open-graded HMA. Other uses include spray applications for bridge deck and pavement protective layer with fabrics. PG64-28 is generally used for the locations with low elevation.

PG70-22: is primarily used in areas with high traffic volume and is also the paving asphalt cement used for the production of Hot Mix Asphalt (HMA). This grade is also a good choice for sealing the edges of pavement and for crack sealing.

PG GRADES WITH THE BEST RESISTANCE IN THERMAL CRACKING

- PG 64 -22

- PG 76 -22

- PG 64 -28

- PG 58 -34

PG GRADES WITH THE BEST RESISTANCE AGAINST RUTTING

- PG 82 -22

- PG 76 -28

- PG 70 -28

- PG 76 -22

Common in toll roads (high Volume): PG 64-22

Common in toll booth (high volume and slow traffic): PG 70-22

Common in rest area (high volume and standing traffic) :PG 76-22

TECHNICAL DATASHEET OF SBS MODIFID BITUMEN PG 76-16

Temperature: 25.0 o c Humidity: 27 %

TEST RESULT STANDARD RANGE STANDARD RANGE TESTS METHOD

MIN MAX

Binder

Penetration @ 250C, 100gr, 5s, O. Imm 53 40 70 ASTM D5

Elastic Recovery @ 250 C, IOCM Elongation (%) 86 80 - ASTM D6084

Softening point, o c 90 70 - ASTM D36

Separation Difference in Softening Point R&B, oc 2.1 - 3 ASTM D7173

Ductility @ 25 0 C 64 25 - ASTM Dl 13

Dynamic Viscosity at 1350 C (Brookfield Viscomeler), Pa.s 1.87 - 3 ASTM D4402

Penetration Index 4.4 2.25 5.25 ASTM D5 / D36

Solubility in TCE (0/0) 99.7 99 - ASTM D2042

Flash Point Temp. oc 340 245 - ASTM D92

Orig. Dynamic Shear @ 76 0C / Kpa 1.94 1 - ASTM D7175

RTFO (D2872)

Penetration of Residue (%) 73 65 - ASTM D5

Ductility @ 25 0 C 48 15 - ASTM Dl 13

Difference in Softening Point, o c -5 -10 5 ASTM D36

RTFO Percent Change Of Mass 0.02 - 0.5 ASTM D1754

RTFO Dynamic shear @ 760 C / Kpa 2.56 2.2 - ASTM D7175

PAV (D6521)

PAV - Dynamic Shear @ 34 0 C / Kpa 652 - 5000 ASTM D7175

PAV Creep Stiffness @ -6 0C / Mpa 46.6 - 300 ASTM D6648

m-Value @ -60 C / M a 0.321 0.3 - ASTM D6648

For more information, please Contact our Sales Team.