HOW TO CONTROL WAX IN BITUMEN ?

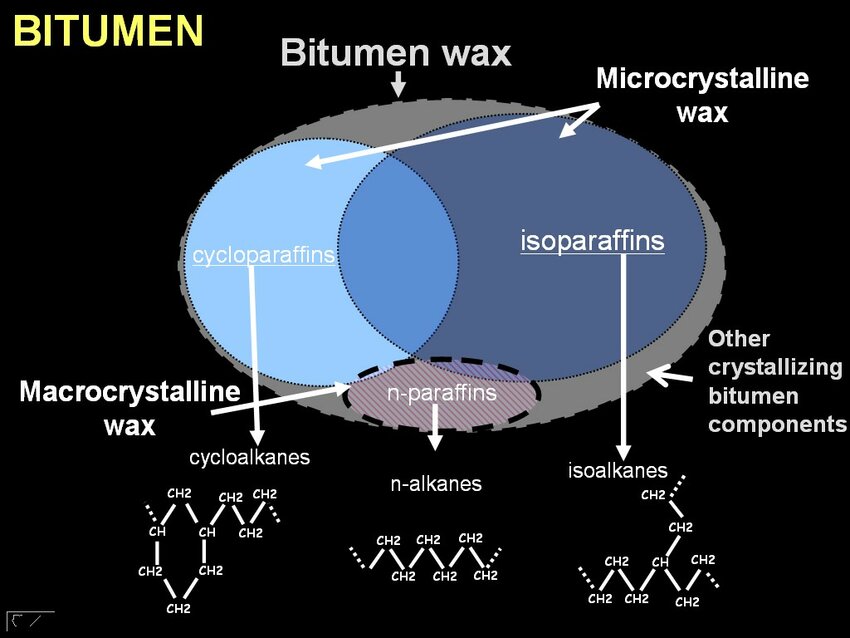

Controlling wax in bitumen involves addressing the issue of wax crystallization, especially in cold temperatures. Wax precipitation in bitumen can lead to an increase in viscosity, making the bitumen more rigid and less workable.

Controlling wax in bitumen involves addressing the issue of wax crystallization, especially in cold temperatures. Wax precipitation in bitumen can lead to an increase in viscosity, making the bitumen more rigid and less workable.

HERE ARE SOME METHODS TO CONTROL WAX IN BITUMEN:

- Additives and Modifiers:

- Polymer Modifiers: Incorporating polymer modifiers, such as styrene-butadiene-styrene (SBS) or styrene-butadiene rubber (SBR), can help improve the low-temperature properties of bitumen and reduce wax crystallization.

- Wax Dispersants: Specialized wax dispersants can be added to the bitumen to prevent the agglomeration of wax particles and inhibit crystallization.

- Blending with Different Grades:

- Blending bitumen with different grades or sources can help achieve a balance in properties, including wax content. This can be effective in achieving desired performance characteristics across a range of temperatures.

- Chemical Additives:

- Anti-wax Agents: Some chemical additives act as anti-wax agents, disrupting the formation of wax crystals in bitumen. These agents can help maintain the fluidity of bitumen at lower temperatures.

- Anti-Oxidants: Oxidation can contribute to wax formation. Anti-oxidant additives can minimize the oxidation process and, consequently, reduce the potential for wax crystallization.

- Temperature Management:

- Storage Temperature: Storing bitumen at higher temperatures can prevent wax precipitation. However, this may not be practical in all situations, especially during transportation or outdoor storage.

- Modified Bitumen Processes:

- Polymer-Modified Bitumen (PMB): Using polymer-modified bitumen, where polymers are added during the production process, can enhance the low-temperature properties of bitumen and reduce wax-related issues.

- Hot Blending:

- Hot Blending Process: Performing hot blending, where bitumen is heated during the mixing process, can reduce the likelihood of wax crystallization. This is particularly useful in preparing bituminous mixes in cold weather.

- Testing and Quality Control:

- Regular testing for wax content and employing quality control measures can help monitor and manage wax-related issues in bitumen.

It’s essential to choose the most suitable method based on the specific requirements and conditions of the project or application. Additionally, consulting with bitumen experts and suppliers can provide valuable insights into addressing wax-related challenges.

For more information, please Contact our Sales Team.