Bituminous Coating

Bituminous Coating

WHAT DOES BITUMINOUS COATING MEAN?

Bituminous coating is also known as asphalt coating. A bituminous coating is a type of coating used to build a vapor-proof and flexible protective coat in accordance with its formulation and polymerization grade. A bituminous coating’s flexibility and protection against vapor and water can be influenced by the polymer grade as well as reinforcement of fiber. The most common applications of a bituminous coating include areas that are beneath screed wet. It is an excellent protective coating and waterproofing agent, especially on surfaces such as concrete foundations. A bituminous coating is a type of protective coating that is made from bitumen, a sticky, black, and highly viscous liquid or semi-solid form of petroleum. This coating is used to protect various surfaces from water, moisture, and corrosion.

A bituminous coating can be used both externally and internally on carbon steel pipes. It is usually black, and when applied properly, the bituminous coating offers outstanding cathodic protection needed for almost all structural steel pipes situated underground. A bituminous coating is regarded as one of the least expensive ways to provide cathodic protection to pipes. It is also the least complex coating process, making it suitable for casing pipes like in road bore. Bituminous coatings are mainly composed of hydrocarbon molecules. Such molecules are elongated, making movement difficult. Therefore, bitumen is solid especially at ambient settings. However, it flows very slowly and is very viscous. Almost all bituminous coatings are ready to use and free from solvent. These are chemical- and UV-resistant, making them reliable protective coatings against wear and corrosion. It can be applied through various methods using a roller, brush or sprayer. It works impressively in waterproofing surfaces, especially on surfaces that are in direct contact with seepage water, moisture and non-pressurized liquid or water.

HERE’S A SIMPLER EXPLANATION:

- Waterproofing: Bituminous coatings are commonly used to waterproof surfaces, such as roofs, basements, and foundations, preventing water penetration and damage.

- Corrosion Resistance: These coatings protect metal surfaces, like pipes and steel structures, from rust and corrosion caused by exposure to moisture and other environmental factors.

- Durability: Bituminous coatings are known for their durability and ability to withstand harsh weather conditions, making them ideal for both residential and industrial applications.

- Flexibility: Depending on the formulation, bituminous coatings can be flexible, allowing them to accommodate structural movements and vibrations without cracking or peeling.

In summary, a bituminous coating is a versatile protective layer used to shield surfaces from water and corrosion, ensuring longevity and durability.

APPLICATION OF COLD APPLIED BITUMEN BASED INSULATING COATINGS IN CONSTRCUTION

Bitumen-based insulating paint is a suitable option for waterproofing many surfaces in construction. This is because we apply it cold. It also provides many benefits in the field of waterproofing, as it is resistant to all weather factors.

BITUMEN-BASED INSULATING PAINT CONSISTS OF THE FOLLOWING COMPONENTS:

1. Bitumen: It is the basic material in insulating paint. Bitumen-based, which is a liquid or viscous substance consisting of a mixture of hydrocarbons. Bitumen has good insulating properties and is resistant to all weather factors, including moisture, heat, and ultraviolet rays.

2. Resins: We add these solid materials to bitumen to increase its strength and stability. Resins have adhesive properties and help improve the water resistance of the paint.

3. Additives: We add these substances to the paint to improve its properties. These include resistance to water, heat, and ultraviolet rays. We characterize them by their own characteristics, such as resistance to water, heat, or ultraviolet rays.

USES OF BITUMEN-BASED INSULATING PAINT IN CONSTRUCTION

WE USE IT IN CONSTRUCTION IN MANY APPLICATIONS, INCLUDING:

- Waterproofing of concrete surfaces: We use it as a primary or final layer for waterproofing systems for concrete surfaces, such as tiled surfaces, ceilings, and surfaces exposed to moisture.

- Insulating building foundations: We also use it to insulate building foundations exposed to moisture or groundwater.

- Insulating internal and external walls and ceilings: We can use it to insulate internal and external walls and ceilings from moisture and groundwater.

- Bonding of bituminous insulating panels: We can use it to bond bituminous insulating panels to increase their effectiveness in insulation.

ADVANTAGES OF BITUMEN-BASED INSULATING PAINT IN CONSTRUCTION

BITUMEN-BASED INSULATING PAINT HAS MANY ADVANTAGES, INCLUDING:

- High resistance to water and moisture: It provides effective protection against water and moisture, making it an ideal choice for external applications, such as insulating roofs, walls, and bathrooms.

- High heat resistance: It has high heat resistance, which makes it a suitable choice for applications in areas with hot climates.

- Resistant to weather factors: It has high resistance to weather factors including moisture, heat, and UV rays, making it a durable, long-lasting option.

- Easy to apply: Bitumen-based insulating paint is easy to apply as you can apply it cold, making it a suitable choice for home applications.

- Environmentally friendly: Bitumen-based insulating paint is free of environmentally polluting materials, so it is an environmentally safe option.

- Resistant to attacks by salts and chemicals: Bitumen insulating paint is based on resistance to attacks by salts and chemicals. This is because bitumen is a natural substance consisting of a mixture of hydrocarbons, which are non-polar molecules that do not interact easily with water or chemicals. This feature makes the bitumen insulating coating waterproof and moisture-resistant, and resistant to chemicals.

- Low Cost: Bitumen-based insulating paint is relatively inexpensive, making it an attractive budget option.

SOME TIPS FOR APPLYING BITUMEN BASED INSULATING PAINT:

- The surface must be well prepared before application begins, by cleaning it and removing any loose or corroded materials.

- You must use a brush, roller, or sprayer to apply the paint.

- Two or three layers of paint should be applied for best results.

In general, bitumen-based insulating paint is a good choice for protection against water, moisture, and chemicals. It is a suitable choice for many applications, including insulating roofs, walls, bathrooms and protecting concrete surfaces.

BITUMINOUS COATING IN WATERPROFFING:

Bituminous Coating in Waterproofing

Bituminous Coating in Waterproofing

A bituminous coating is widely used in waterproofing applications to protect structures from water infiltration and damage. Bitumen, which is the most crucial part of bitumen waterproofing, is a hydrocarbon composition found in deposits such as oil sands and pitch lakes or obtained by distillation of crude oil in refineries. During the distillation process as lighter components rise to the top, heavy components, including the bitumen, fall to the bottom of the column. After removing lighter fractions such as liquid petroleum gas, gasoline, and diesel from crude oil during the refining process, residual component is called as bitumen. The grade of bitumen can change up to how much volatile material remains in the distilled bitumen. The bitumen can be used as a raw material or as a mix depending on application areas. It can be used as a binder in asphalt for roads, runways, parking lots, foot paths. It is also used as mix in building and construction sector from basement to roofing to provide excellent waterproofing quality. Bitumen can be modified with polymers to enhance its performance and using as different forms of product in building industry. It serves as the main component of waterproofing materials in forms of sealants, mastics, adhesive, coating etc.

WHY BITUMEN IS POPULAR IN WATERPROOFING SECTOR?

Bitumen in Waterproofing

Bitumen in Waterproofing

First of all, bitumen has an economic process. Bitumen, which remains after crude oil distillation process, is a by-product When primary products such as petrol, diesel, high octane fuels and gasoline are refined, the bitumen is left behind. Besides, bitumen is a versatility product. It shows viscoelastic and thermoplastic behaviors. Bitumen has both viscous and elastic behaviors depending on the temperature and loading time. At high- temperature or in long loading times, bitumen behaves as a viscous material. At low temperatures or in fast loading mode bitumen behaves like an elastic solid. The melting point of the bitumen is not so high that it can be melted easily during the application. The bitumen has a highly adhesive nature, which keeps the materials together strongly. All these features prove that bitumen waterproofing is one of the most convenient solutions up to usage areas.

HERE’S A DETAILED EXPLANATION OF HOW IT WORKS AND ITS BENEFITS:

- Composition:

- Bitumen-Based: The coating is primarily made of bitumen, a byproduct of crude oil distillation, which is mixed with other materials to enhance its properties.

- Additives: Various additives like polymers, fillers, and solvents are often included to improve flexibility, adhesion, and overall performance.

- Application:

- Surface Preparation: The surface to be waterproofed is cleaned and primed to ensure proper adhesion.

- Coating Process: The bituminous coating is applied in layers using brushes, rollers, or spray equipment. It can be applied to various surfaces, including concrete, metal, and wood.

- Curing: Once applied, the coating needs time to cure and form a seamless, continuous barrier.

- Mechanism:

- Water Barrier: Bitumen forms an impermeable barrier that prevents water from passing through. This is crucial for protecting the underlying materials from water damage.

- Flexibility: The coating remains flexible even after curing, which allows it to move with the structure without cracking, ensuring long-lasting protection.

BENEFITS OF BITUMINOUS COATING IN WATERPROOFING

- Effective Waterproofing:

- Impermeability: It creates a strong, impermeable layer that effectively blocks water and moisture, safeguarding the structure from leaks and dampness.

- Seamless Protection: When applied correctly, it forms a seamless layer without joints or seams, which are potential points of failure in other types of waterproofing systems.

- Versatility:

- Multiple Surfaces: Suitable for a variety of surfaces such as foundations, basements, roofs, and retaining walls.

- Compatibility: It can be used over different construction materials including concrete, masonry, and metal.

- Durability:

- Long-Lasting: Bituminous coatings are known for their durability and ability to withstand harsh environmental conditions, including UV radiation, temperature fluctuations, and chemical exposure.

- Resistant to Roots: Ideal for green roofs and landscaped areas as it resists root penetration.

- Cost-Effective:

- Affordable: Compared to other waterproofing solutions, bituminous coatings are generally cost-effective, offering good protection at a lower price.

- Ease of Application: The application process is straightforward, reducing labor costs and application time.

COMMON USES IN WATERPROOFING

- Foundations and Basements: Protects below-ground structures from water ingress.

- Roofs: Provides a waterproof layer for flat and pitched roofs.

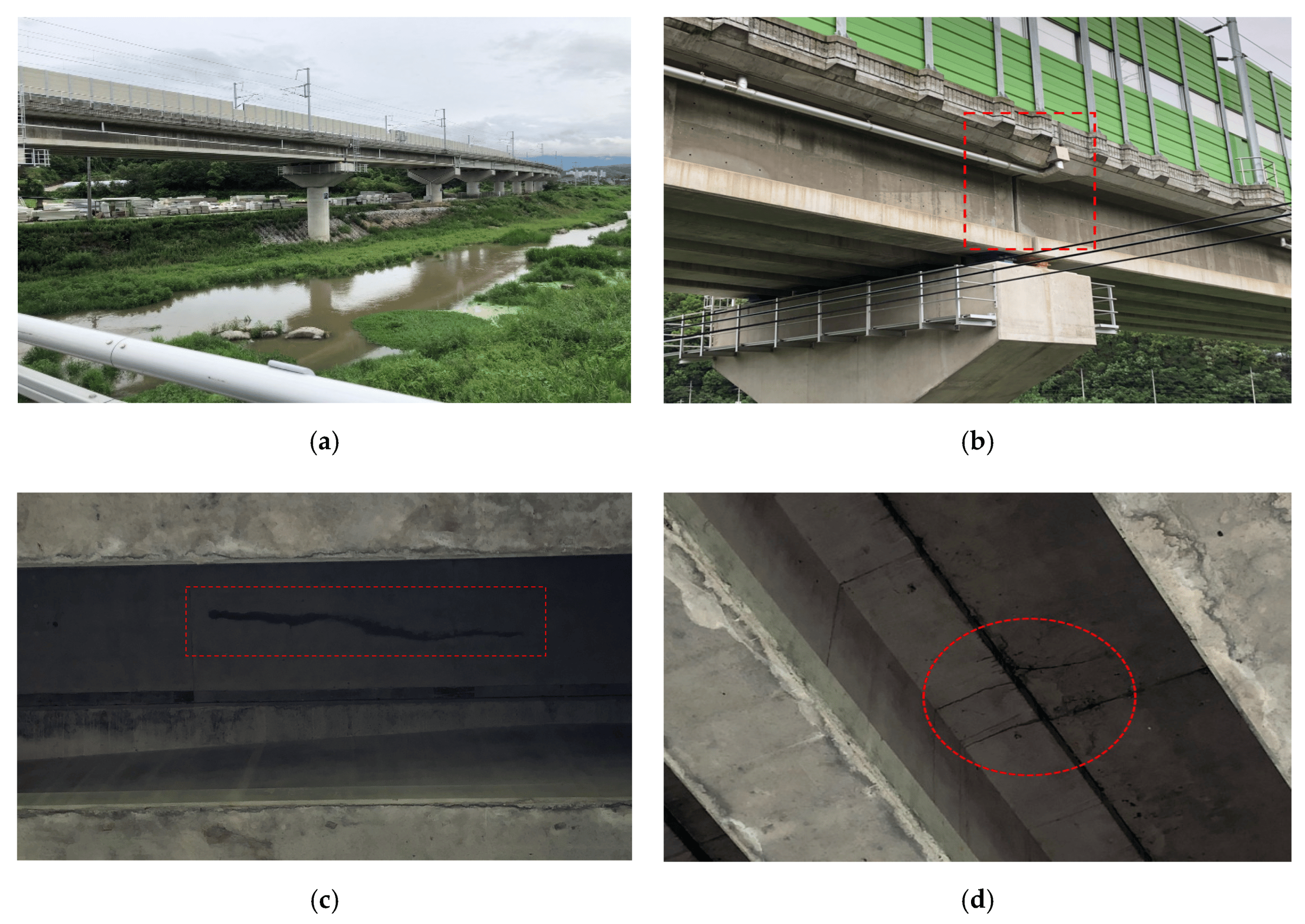

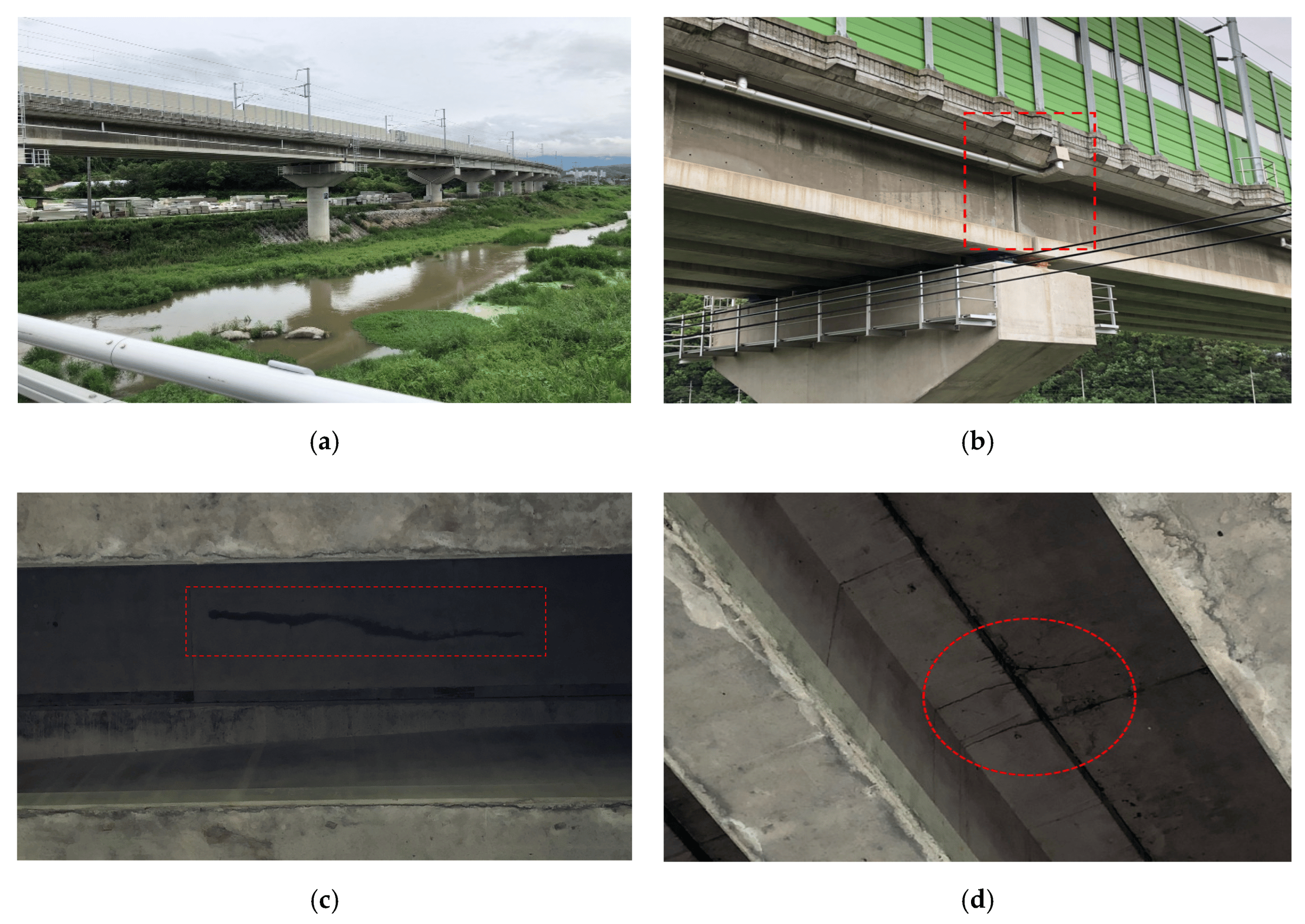

- Bridges and Tunnels: Used in civil engineering projects to protect concrete structures.

- Balconies and Terraces: Ensures these outdoor areas remain watertight and protected from water damage.

In summary, bituminous coating is a highly effective, versatile, and durable solution for waterproofing various structures. It provides a reliable barrier against water infiltration, ensuring the longevity and integrity of the protected surfaces.

BITUMINOUS COATING IN CORROSION RESISTANCE:

Bituminous Coating Works in Corrosion Resistance

Bituminous Coating Works in Corrosion Resistance

A bituminous coating is a protective layer applied to various surfaces to prevent corrosion, particularly on metal structures. Bituminous coatings are highly effective in providing corrosion resistance for metal structures. Composed primarily of bitumen, these coatings create a thick, impermeable barrier that prevents moisture, oxygen, and corrosive chemicals from reaching the metal surface. The inclusion of polymers and fillers enhances their flexibility, adhesion, and durability, making them resistant to environmental stresses such as temperature fluctuations and UV exposure. Applied in multiple layers, bituminous coatings are tough and resilient, offering robust mechanical and abrasion resistance. This makes them ideal for protecting pipelines, storage tanks, marine structures, and industrial equipment. Their chemical resistance extends to a wide range of corrosive agents, including acids, alkalis, and salts, ensuring long-lasting protection. Additionally, bituminous coatings are cost-effective and easy to apply, reducing the need for frequent maintenance and repairs. Their flexibility allows them to accommodate structural movements and temperature changes without cracking, maintaining a seamless protective layer. Overall, bituminous coatings are a versatile and reliable solution for extending the lifespan of metal structures by effectively preventing corrosion.

HERE'S A DETAILED EXPLANATION OF HOW IT WORKS AND ITS BENEFITS IN CORROSION RESISTANCE:

HOW BITUMINOUS COATING WORKS IN CORROSION RESISTANCE

- Composition:

- Bitumen-Based: The primary component is bitumen, which is mixed with other substances like polymers and fillers to enhance its properties.

- Additives: These additives improve the coating’s adhesion, flexibility, and overall effectiveness in protecting against corrosion.

- Application:

- Surface Preparation: The metal surface is cleaned to remove rust, dirt, and other contaminants, ensuring good adhesion of the coating.

- Coating Process: The bituminous coating is applied using brushes, rollers, or spray equipment. Multiple layers might be applied to achieve the desired thickness.

- Curing: The coating is allowed to cure, forming a tough, continuous protective layer over the metal surface.

- Mechanism:

- Barrier Protection: The bituminous coating creates an impermeable barrier that blocks moisture, oxygen, and other corrosive agents from reaching the metal surface.

- Adhesion and Flexibility: It adheres well to metal surfaces and remains flexible, allowing it to expand and contract with temperature changes without cracking or peeling.

BENEFITS OF BITUMINOUS COATING IN CORROSION RESISTANCE

- Effective Corrosion Protection:

- Moisture Barrier: It prevents water and moisture from reaching the metal, which are primary contributors to corrosion.

- Chemical Resistance: The coating resists a variety of chemicals, including acids and salts, which can accelerate corrosion processes.

- Durability:

- Long-Lasting Protection: Bituminous coatings are highly durable and can provide long-term protection against corrosion.

- Weather Resistance: They can withstand harsh environmental conditions, including UV radiation, extreme temperatures, and abrasion.

- Flexibility:

- Adaptability: The coating remains flexible even after curing, accommodating structural movements and vibrations without losing adhesion or cracking.

- Thermal Stability: It performs well across a wide range of temperatures, maintaining its protective qualities in both hot and cold environments.

- Versatility:

- Multiple Applications: Bituminous coatings can be used on various metal structures, including pipes, tanks, bridges, and marine equipment.

- Compatibility: Suitable for use on different metals such as steel, iron, and aluminum, providing a broad range of applications.

COMMON USES IN CORROSION RESISTANCE

- Pipelines and Tanks:

- Protection for Underground and Aboveground Structures: Bituminous coatings are commonly used to protect pipelines and storage tanks from soil and atmospheric corrosion.

- Marine Structures:

- Ships and Offshore Platforms: The coating provides a reliable barrier against the harsh marine environment, preventing saltwater corrosion on ships, docks, and offshore platforms.

- Bridges and Infrastructure:

- Steel Bridges and Supports: Protects structural steel in bridges and other infrastructure from rust and corrosion, extending their lifespan.

- Industrial Equipment:

- Machinery and Metal Parts: Applied to industrial machinery and metal parts exposed to corrosive chemicals and harsh operating conditions.

In summary, bituminous coating is a highly effective solution for corrosion resistance. It creates a robust, impermeable barrier that protects metal surfaces from moisture, chemicals, and environmental factors that cause corrosion. Its durability, flexibility, and versatility make it an ideal choice for a wide range of applications in various industries.

BITUMINOUS COATING IN DURABILITY:

Bituminous Coating in Durability

Bituminous Coating in Durability

A bituminous coating is known for its exceptional durability, making it a popular choice for protecting structures and surfaces. Bituminous coatings are renowned for their exceptional durability, making them a preferred choice for protecting various structures. These coatings form a robust, impermeable layer that shields surfaces from moisture, chemicals, and physical wear. Composed primarily of bitumen, enhanced with polymers and fillers, they exhibit remarkable resistance to environmental stresses, including extreme temperatures, UV radiation, and weathering. The flexibility of bituminous coatings allows them to expand and contract with structural movements and temperature fluctuations without cracking, maintaining their integrity over time. Their abrasion resistance ensures they can withstand heavy traffic and mechanical impacts, making them suitable for high-traffic areas and industrial applications. Additionally, bituminous coatings resist degradation from chemicals, such as acids and alkalis, further enhancing their longevity. Their ease of application and maintenance reduces long-term costs, as they require fewer repairs and reapplications compared to other coatings. Overall, the durability of bituminous coatings makes them a reliable solution for extending the lifespan of surfaces, providing long-lasting protection against a variety of damaging factors.

HERE’S A DETAILED EXPLANATION OF WHY BITUMINOUS COATINGS ARE SO DURABLE AND THE BENEFITS THEY OFFER:

HOW BITUMINOUS COATING ENSURES DURABILITY

- Composition:

- Bitumen-Based: The primary component is bitumen, which is naturally sticky, viscous, and highly resistant to wear and tear.

- Additives: Polymers, fillers, and other additives are mixed with bitumen to enhance its properties, improving flexibility, adhesion, and resistance to environmental factors.

- Application Process:

- Surface Preparation: Proper cleaning and priming of the surface ensure that the bituminous coating adheres well and provides maximum protection.

- Layering: The coating is typically applied in multiple layers, which builds up a thick, robust protective barrier.

- Curing: The coating is allowed to cure, forming a solid, continuous layer that adheres tightly to the surface.

DURABILITY FEATURES OF BITUMINOUS COATING

- Resistance to Environmental Factors:

- Waterproofing: Bituminous coatings are highly effective at creating a waterproof barrier, preventing water infiltration and protecting against moisture damage.

- UV Protection: These coatings are resistant to UV radiation, which prevents degradation and maintains their protective qualities over time.

- Temperature Stability: Bituminous coatings can withstand extreme temperatures, from very high to very low, without cracking or losing adhesion.

- Physical Durability:

- Flexibility: Even after curing, bituminous coatings remain flexible, allowing them to expand and contract with temperature changes and structural movements without breaking or peeling.

- Abrasion Resistance: The coatings are tough and resistant to physical wear and tear, making them suitable for high-traffic areas and surfaces exposed to rough conditions.

- Chemical Resistance:

- Corrosion Prevention: Bituminous coatings protect metal surfaces from corrosion caused by exposure to air, water, and chemicals.

- Chemical Stability: They are resistant to a variety of chemicals, including acids, bases, and salts, which helps in maintaining their integrity in harsh environments.

BENEFITS OF BITUMINOUS COATING’S DURABILITY

- Long-Lasting Protection:

- Extended Lifespan: Structures and surfaces protected by bituminous coatings enjoy a significantly extended lifespan due to the robust protective layer.

- Reduced Maintenance: The durability of bituminous coatings means less frequent maintenance and repairs, saving time and costs in the long run.

- Versatility:

- Wide Range of Applications: Suitable for a variety of surfaces including concrete, metal, wood, and masonry, used in different industries from construction to marine.

- Multiple Uses: Commonly applied to roofs, foundations, basements, bridges, pipes, and tanks to ensure lasting protection.

- Cost-Effectiveness:

- Affordable Protection: Bituminous coatings offer an economical solution for long-term protection against water, UV rays, and chemicals.

- Efficiency: Easy application and fast curing times make them a practical choice for large-scale and small-scale projects alike.

COMMON USES SHOWCASING DURABILITY

- Roofing:

- Weatherproofing: Protects roofs from rain, snow, and UV radiation, ensuring they remain intact and leak-free.

- Foundations and Basements:

- Moisture Barrier: Prevents water ingress and protects the structural integrity of buildings.

- Industrial and Marine Applications:

- Corrosion Resistance: Protects pipes, tanks, and metal structures from corrosion in harsh industrial and marine environments.

- Infrastructure:

- Structural Protection: Extends the life of bridges, tunnels, and other infrastructure by shielding them from environmental damage.

In summary, the durability of bituminous coating lies in its robust composition, flexibility, and resistance to environmental, physical, and chemical stressors. This makes it an ideal choice for long-lasting protection across a wide range of applications.

BITUMINOUS COATING IN FLEXIBILITY:

Bituminous Coating in Flexibility

Bituminous Coating in Flexibility

A bituminous coating is renowned for its flexibility, which is one of the key attributes contributing to its widespread use in various protective applications. Bituminous coatings exemplify unparalleled flexibility, making them a cornerstone in protective solutions for diverse surfaces. Composed primarily of bitumen, these coatings boast inherent pliability and resilience. Infused with additives like polymers, they exhibit enhanced flexibility, enabling them to conform seamlessly to the contours of substrates. This flexibility allows bituminous coatings to accommodate structural movements and temperature variations without compromising their integrity. Whether applied to roofs, bridges, or industrial equipment, these coatings adapt effortlessly to dynamic conditions, ensuring enduring protection against environmental stressors. Their ability to flex prevents cracking or peeling, maintaining a seamless barrier against moisture, chemicals, and physical abrasion. Bituminous coatings excel in high-traffic areas, withstanding heavy loads and frequent use without deterioration. Their ease of application and maintenance further underscores their practicality, offering cost-effective solutions for long-term surface protection. In essence, bituminous coatings epitomize flexibility, providing robust defense while accommodating the dynamic demands of diverse applications.

HERE’S A DETAILED EXPLANATION OF THE FLEXIBILITY OF BITUMINOUS COATINGS AND THE BENEFITS IT OFFERS:

HOW BITUMINOUS COATING ENSURES FLEXIBILITY

- Composition:

- Bitumen Base: The primary component, bitumen, is a naturally flexible material. It is a semi-solid form of petroleum that is inherently sticky and pliable.

- Additives: Polymers and other modifiers are often added to bitumen to enhance its flexibility. These additives help the coating maintain its elasticity over a wide range of temperatures.

- Application Process:

- Layering: The bituminous coating is applied in multiple layers, creating a thick, resilient membrane that can move with the underlying surface.

- Curing: Once applied, the coating undergoes a curing process, forming a continuous, flexible barrier that adheres tightly to the surface.

FLEXIBILITY FEATURES OF BITUMINOUS COATING

- Thermal Flexibility:

- Temperature Variability: Bituminous coatings remain flexible across a wide temperature range. They can expand and contract with temperature fluctuations without cracking or losing adhesion.

- Cold and Heat Resistance: The coating maintains its flexibility in both extremely cold and hot environments, making it suitable for various climatic conditions.

- Structural Adaptability:

- Movement Accommodation: The flexible nature of bituminous coatings allows them to accommodate structural movements, such as settling, vibrations, and thermal expansion and contraction.

- Crack Bridging: They can bridge small cracks and gaps in the substrate, preventing water ingress and maintaining the integrity of the protective barrier.

BENEFITS OF BITUMINOUS COATING’S FLEXIBILITY

- Durability:

- Long-Lasting Protection: The ability to flex without breaking or cracking ensures long-term protection for the underlying surface, reducing the need for frequent repairs and maintenance.

- Resistance to Environmental Stress: Flexible bituminous coatings can withstand environmental stresses, such as temperature changes, UV radiation, and mechanical impacts, without deteriorating.

- Versatility:

- Wide Range of Applications: The flexibility of bituminous coatings makes them suitable for various surfaces and structures, including roofs, foundations, basements, bridges, and industrial equipment.

- Compatibility: They can be applied to different materials, including concrete, metal, wood, and masonry, providing effective protection in diverse settings.

- Enhanced Performance:

- Waterproofing: The flexible nature of bituminous coatings ensures a continuous, seamless waterproof barrier that adapts to the surface, preventing water penetration.

- Corrosion Resistance: By maintaining a tight bond to metal surfaces and accommodating movements, the coating effectively prevents moisture and corrosive elements from reaching the metal.

COMMON USES SHOWCASING FLEXIBILITY

- Roofing:

- Weather Adaptation: Bituminous coatings on roofs can expand and contract with temperature changes, preventing leaks and maintaining waterproofing.

- Foundations and Basements:

- Movement Accommodation: Protects against structural movements and settlements, ensuring a continuous waterproof barrier around foundations and basements.

- Bridges and Infrastructure:

- Vibration Resistance: Flexible coatings on bridges and infrastructure can handle vibrations and dynamic loads, protecting the underlying materials from damage.

- Industrial Applications:

- Equipment Protection: Bituminous coatings on industrial equipment and metal structures provide a flexible, corrosion-resistant barrier that adapts to thermal and mechanical stresses.

In summary, the flexibility of bituminous coatings makes them an ideal choice for providing long-lasting, adaptable protection in a variety of applications. Their ability to expand and contract with environmental and structural changes ensures the integrity and effectiveness of the protective layer, contributing to the durability and performance of the coated surfaces.

For more information, please Contact our Sales Team.

Bituminous Coating

Bituminous Coating Bituminous Coating in Waterproofing

Bituminous Coating in Waterproofing Bitumen in Waterproofing

Bitumen in Waterproofing

Bituminous Coating Works in Corrosion Resistance

Bituminous Coating Works in Corrosion Resistance Bituminous Coating in Durability

Bituminous Coating in Durability Bituminous Coating in Flexibility

Bituminous Coating in Flexibility