Polybutadiene Rubber

Polybutadiene Rubber

BUTADIENE RUBBER?

Butadiene rubbers, produced by the solution polymerization process, have a very high elasticity and degree of resistance to dynamic stress and retain these properties even at extremely low temperature. Blending natural rubber or styrene butadiene rubber with PBR improves the abrasion resistance, crack resistance and heat build-up under dynamic load.

WHAT IS POLYBUTADIENE RUBBER – PBR?

The most important applications of this product are in the production of tires and rubber parts. It was one of the first types of elastomer or synthetic rubber that was invented. Since this polymer is very similar to natural rubber, namely polyisoprene, its use as an elastomer did not require much thought. This rubber is suitable for applications dealing with low temperatures. Car tires are often made of polybutadiene copolymers. Belts, hoses, gaskets and other car parts are also made of polybutadiene, because it shows better resistance to low temperatures than other polymers. Many polymers become brittle at low temperatures as a result of a phenomenon called glass transition. Hard rubber, called polystyrene, polybutadiene or rubber, is a copolymer containing polybutadiene.

HISTORY AND HOW TO PRODUCE BUTADIENE RUBBER

Polybutadiene was among the first elastomers or rubbers that were invented, 70% of the produced polybutadiene is used to make rubber and tires, and 25% to 30% of it is added as an additive to other tires to increase their mechanical strength. The annual production of this polymer in 1380 was more than 2.1 million tons, which ranks second among tires in terms of tonnage consumption, after Styrene Butadiene Rubber or Styrene Butadiene Rubber. Polybutadiene for the first time In 1910, it was polymerized by a Russian scientist named Sergei Vasilyevich Lebedev. In 1926, he invented a process to produce butadiene from ethanol, and in 1928, he was able to use sodium as a catalyst to develop the production of polybutadiene. . According to this discovery, the Soviet Union was the first country that succeeded in the industrial production of this polymer in the late 1930s. Among the countries that contributed a lot to the research and development of polybutadiene production were Germany and America. After World War II, in the mid-1950s, major advances in the field of catalysts, especially Ziegler Nata catalysts, led to the production of new and improved types of polymers, including polybutadiene.

In order to obtain the desired properties, polybutadiene rubber is used as an alloy with natural rubber and styrene to produce SBR and HIPS, and acrylonitrile to produce ABS, and in this case it has high abrasion resistance and resilience. The most versatile additive. What is added to polybutadiene is Anti-Oxidant.

APPLICATION OF BUTADIENE RUBBER – PBR

The high abrasion resistance and resistance to cracking of butadiene rubber has caused it to be used in most of the tire tread compounds. It is most widely used in the manufacture of passenger car, truck and racing car tires. Also, tire treads are made of polybutadiene copolymers. Butadiene rubber is used in the manufacture of shoes, belts and conveyor belts, rubber sponges, hoses and gaskets, golf balls.

ADVANTAGES OF PBR PBR 1220

Versatility: SBR rubber can be used in a wide range of applications, from automotive to household goods, making it a versatile material for manufacturers.

Performance: Its excellent mechanical properties, such as high tensile strength and wear resistance, ensure long-term performance in harsh environments.

Economic Advantage: The cost-effectiveness of SBR rubber makes it an attractive option for manufacturers looking to produce high-quality, low-cost products.

Sustainability: As a synthetic rubber, SBR reduces dependence on natural rubber and contributes to sustainable production methods.

Application:

1- Automotive industry: One of the main uses of SBR rubber is in the automotive industry. Due to its durability and wear resistance, this rubber is used in the production of tires, washers and seals.

Tires: Car tires need materials that can withstand high wear, repeated impacts and different temperatures. Due to its durability and flexibility, SBR is one of the main materials in the production of car tires.

Gaskets O-rings: SBR’s resistance to tearing and wear makes it ideal for the production of automotive gaskets and seals that require high precision and tolerance.

2- Shoe industry: SBR rubber is a key material in the production of shoe soles and boots, which has excellent adhesion and long life.

Shoe soles: SBR is a good choice for sports and everyday shoe soles due to its flexibility and wear resistance.

Boots: In the production of boots, SBR is used due to its resistance to harsh environmental conditions and maintaining flexibility at low temperatures.

Construction Industry: In the construction industry, SBR is used for flooring, adhesives, and sealants due to its strong adhesive properties and flexibility (although it may not be used alone in these products, but by compounding it with other rubbers).

Floors: Floors made of SBR are used in high-traffic places such as gyms and offices due to their wear resistance and ability to withstand heavy loads.

- Water resistance

- Resistance to bending cracking

- Resistance to weathering

- Abrasion Resistance

- Resistance to sunlight

- Flexibility at low temperature

- pressure mana

- Tear resistance

- Impermeable to gases

- Impact resistance

- Resistance to shear growth

- Resistance to alcohols

- Resistance to vegetable and animal oils

- Resistance to acids

- Resistance to alkalis

- Resistance to oxidation

DISADVANTAGES OF PBR RUBBER

- heat resistance

- It does not have low ignition delay

- Low resistance to oil and gasoline

- Unfavorable processability

- Low resistance to ozone

REMARKS

This rubber has properties similar to natural rubber NR, isoprene and SBR and has the lowest glass transition temperature (except for silicones) and performs well at low temperatures even up to -60 degrees. To obtain the desired properties, it is mainly used as an alloy with other rubbers. For example, the mixture of BR and SBR in rubber is the right combination that is used today.

Polybutadiene was among the first elastomers or rubbers that were invented, 70% of the produced polybutadiene is used to make rubber and tires, and 25% to 30% of it is added as an additive to other tires.

FLAMMABILITY CHARACTERISTICS OF BUTADIENE RUBBER

- It burns in the flame and continues to burn after the flame is removed.

- It has an orange-yellow flame and crackles a little.

- Black smoke contains carbon particles.

- It does not drip in the flame.

- It smells of burnt rubber and unpleasant

SAFETY AND STORAGE GUIDELINES FOR POLYBUTADIENE RUBBER

HANDLING:

Protective Gear: Wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and protective clothing to avoid skin contact or eye irritation.

Ventilation: Ensure proper ventilation in areas where PBR 1220 is processed or stored to avoid inhaling any fumes or dust.

Fire Safety: PBR 1220 is flammable. Avoid exposure to open flames, sparks, or other sources of ignition. Use explosion-proof equipment in processing areas.

HEALTH RISKS:

Inhalation: Inhalation of fumes or dust can cause respiratory irritation. Use respiratory protection in areas with poor ventilation.

Skin Contact: Prolonged or repeated contact with PBR 1220 may cause skin irritation. Wash thoroughly after handling.

Eye Contact: In case of eye contact, rinse immediately with plenty of water and seek medical attention if irritation persists.

FIRST AID MEASURES:

Inhalation: Move the affected person to fresh air. If breathing is difficult, provide oxygen and seek medical attention.

Skin Contact: Wash the affected area with soap and water. Remove contaminated clothing.

Eye Contact: Rinse with plenty of water for at least 15 minutes. Seek medical attention if irritation continues.

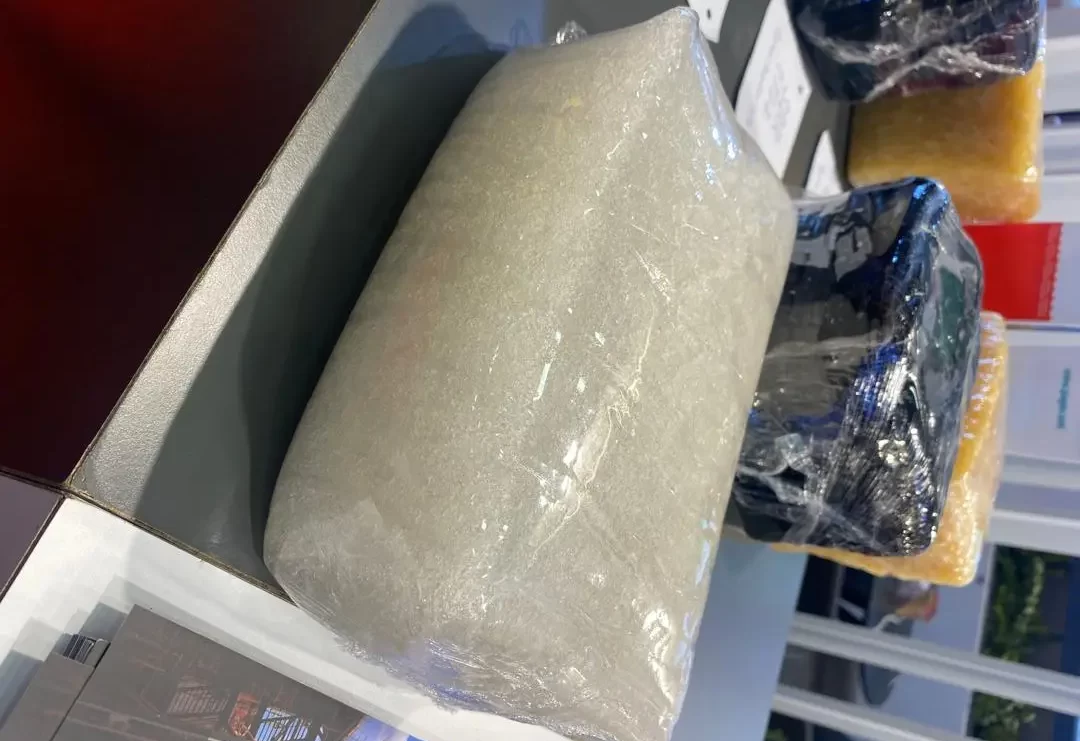

PACKING OF POLYBUTADIENE RUBBER

- 35 ±0.5 KG Bales Wrapped with Polyethylene film

- 36 Bales per Crate (1260±18 KG)

HIGH CIS POLYBUTADIENE RUBBER (PBR)

NO Grades Mooney Viscosity

(ML 1+4@100°C)

Volatile matter (%) Application

1 1220 41-49 Max 0.75 Automobile tires, conveyor belts, footwear, cables, hosepipes and various technical rubber goods.

2 1220C 43-53 Max 2 Automobile tires, conveyor belts, footwear, cables, hosepipes and various technical rubber goods.

3 1202 30-40 Max 0.75 Low gel, suitable for HIPS production

TECHNICAL DATA SHEET OF PBR 1220

Item Unit Specification Result Test Method

Raw Mooney Viscosity MU 41- 49 45 ASTM D1646-07

Cis Content WT% Min. 96 96.4 Internal Method

Volatile Matter Content WT% Max. 0.75 0.5 ASTM D5668-

09

Ash Content WT% Max. 0.3 0.07 ASTM D1416

Compound1 Mooney Viscosity MU Max. 77 71 ASTM D1646

Tensile Strength (35 min) Kg.f/cm³ Min. 150 162 ASTM D412-06

Elongation at Break (35min) % Min. 440 460 ASTM D412-06

300% Modulus at 145°C

25 Min kg/cm² 68 - 108 76 ASTM D412-06

35 Min kg/cm² 74 -114 92 ASTM D412-06

50 Min kg/cm² 74 - 114 92 ASTM D412-06

For more information, please Contact our Sales Team.