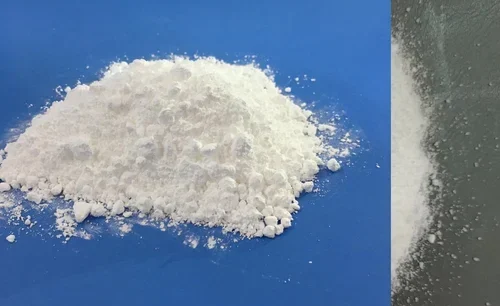

Polyethylene Wax Powder Description

Polyethylene Wax Powder, whose Latin name is PE WAX and is also called wax powder for short, has an extremely low molecular weight. Polyethylene wax powder is a kind of by-product of polyethylene and has forms such as HDPE and LDPE. It is worth noting that wax powder also has a wax-like state and is very slippery and smooth. For this reason, it is also used as a lubricant option. Polyethylene is odorless and colorless and has a transparent and crystal-like state. In addition, polyethylene can be produced in two forms and emulsion and non-emulsion forms. These two samples differ from each other in terms of molecular mass, while polyethylene wax, like other Polyethylenes, is not flexible and also has less resistance. However, polyethylene wax has good resistance to chemicals and environmental stresses. It benefits from several properties. This wax is formed through a process called polymerization.

Pe Wax Powder Types

Polyethylene Wax Powder is produced through a polymerization process. The distinction in its three main characteristics can cause differences between the types of polyethylene wax, which are: I) molecular weight, II) degree and length of polymer branching and III) monomer / polymer composition.

A change in any of these factors can change the physical properties of this material, including viscosity, hardness, melting point, reactivity, etc. It can also be activated by performing an oxidation process, which is actually the addition of acid and ester functional groups to polyethylene wax.

The resulting product is a polar oxide and has very different properties. On the other hand, this makes it more compatible with polar materials such as PVC. In general, although a polyethylene wax manufacturer often tries to improve product quality by changing the polymerization process, some properties are common to all of these products.

How is Pe Wax Powder Produced?

First, it should be noted that polyethylene wax powder, or powdered polyethylene wax, is a by-product of the polyethylene production process. To do this, ethylene gas is first dissolved in hexane and polymerization is carried out using a catalyst and a three-phase reactor. Of course, it should be noted that there is another type of polyethylene wax powder, the production method of which is to use the method of breaking the molecular chain of linear polyethylene. It should be noted that the word wax generally refers to organic materials with a wide variety. These types of materials have solid properties at normal temperatures, while at higher temperatures, they will turn into a liquid state.

Application of Polyethylene Wax

According to the characteristics of polyethylene wax powder that were explained, polyethylene wax powder is widely used in various industries, the most important of which we will mention below: Polyethylene wax powder is a suitable option for waterproofing. For this reason, wax powder is used in the manufacture and production of various models of wood composites, such as chipboard, MDF, OSB boards and other products that use wood. Another area of application of polyethylene wax powder is the manufacture of various types of candles. As you know, candles are not only used for lighting and have a variety of applications. For PVC pipes, a type of lubricant and flame retardant called chlorinated paraffin is used. In the production of this material, polyethylene wax powder also shows its application and role.

The widespread use of powdered polyethylene wax in various industries fully proves the advantages and advantages of this material, the most important of which are briefly mentioned below:

- Affordable price

- Very good adhesion

- An excellent lubricant

- Possibility of creating very good compatibility with other materials

- Widely used in specific industries and products such as the plastics industry due to its high molecular weight.

Packing

1. BAGS:

Multi-layer Paper Bags: These often include an inner layer of polyethylene or polypropylene to provide moisture resistance.

Plastic Bags: Made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), providing good barrier properties against moisture and contamination.

2. SACKS:

Woven Polypropylene Sacks: Durable and resistant to tearing, suitable for heavier loads.

3. FIBER DRUMS:

Cylindrical containers: often with a polyethylene liner, used for larger quantities.

Typical Packaging Sizes:

- Small Bags: 20 kg (44 lbs)

- Large Bags: 25 kg (55 lbs)

- Bulk Packaging: Up to 500 kg (1102 lbs) in big bags

Example Packing Specification:

Material: Polyethylene Wax (PE wax) powder

Packaging Type: 25 kg multi-layer paper bag with an inner polyethylene liner

Quantity per Pallet: 40 bags

Total Weight per Pallet: 1000 kg

Label: Product name, weight, batch number, safety information

Technical Datasheet of Powder Pe Wax

Characteristic value Unit

Density 0.93±0.03 g/Cm3

Appearance Powder --

Melting Point 110±5 C

Color White --

Penetration Hardness 3 d.mm

Softening Point 85-105 C

Supplier of Polyethylene wax powder

We are a supplier of Polyethylene wax powder. With years of experience in the industry, we have built a reputation for delivering high-quality products to our clients across Turkey, Romania, Bulgaria, Serbia, Ukraine, Bosnia, Poland, Greece, Oman, Iraq, Pakistan, India, Taiwan, Thailand, and Vietnam. However, our team will assist at every step to ensure a smooth and timely supply. (Contact Us)