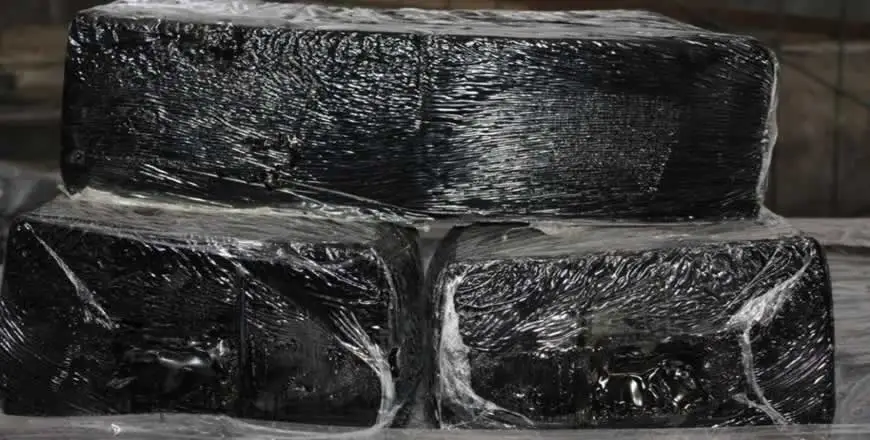

Oxidized Bitumen 90/10 Raha Oil is a reliable supplier and exporter of Oxidized Bitumen 90/10, supplying high-quality blown asphalt from Dubai, UAE to customers across the GCC, Africa, Asia, and global markets. Oxidized Bitumen 90/10 is a semi-solid industrial bitumen grade with excellent thermal stability, durability, and chemical resistance, making it ideal for a wide range of construction and industrial applications. Oxidized Bitumen 90/10 (in another word, oxidized bitumen 90/10, blown bitumen 90/10) is Semi Solid grade of pure petroleum bitumen manufactured by air-blowing through an asphalt flux. Special physical properties of its grade can be used in different applications in the construction business. Oxidized asphalt 90/10 is based on petroleum bitumen which is made by oxidized asphalt 60/70 by hot air. The numbers relate to the midpoint of the material’s softening point and penetration respectively. The softening point value is the degrees Centigrade measured by the Ring and Ball method as determined by ASTM D36. The penetration value is in 1/10 mm as determined by IP49 or ASTM- D5. Oxidized asphalt 90/10 with the arrangement of the international inspector to check quality and quantity of the Oxidized asphalt 90/10 during the loading to the vessel and controlling the production by QC by batch test report before shipping. The foregoing Table sets out the characteristics of several 85-100 pen asphalt cements. As mentioned above, in various countries, asphalt cements are graded by penetration. In other countries, such as the United States, asphalts are graded persuant to viscosity. Asphalt precursors may be categorized, not only by penetration, but also by viscosity. Accordingly, in reference to ASTM standards, a “high quality paving asphalt precursor” is a vacuum tower bottom residue from refining of crude or crude blends suitable for production of paving asphalt cements meeting the requirements specified in ASTM D-3381, Table 2. A “low quality paving asphalt precursor” is a vacuum tower bottom residue from refining of crude or crude blends which are not suitable for production of paving asphalt cement meeting requirements specified in ASTM D-3381, Table 2, but are suitable for production of asphalts meeting the requirements specified in ASTM D-3381, Table 1. Further, a “non-paving asphalt precursor” is vacuum tower bottom residue from refining of crude or crude blends which are not suitable for production of asphalt cement meeting the requirements specified in ASTM D-3381 Table 1 or Table 2. High quality paving asphalt cements may be obtained by careful selection of the crude oil from which the asphalt cement is to be made and the operating conditions used to obtain the vacuum tower bottoms. By making an appropriate selection, a high quality paving asphalt cement may be obtained. Such crude oils and operating conditions are known to those in the art. For ease of reference such VTB and similar materials which may be used as a high quality paving asphalt cement or from which a high quality paving Oxidized bitumen 90/10 is obtained comprise the high quality paving asphalt precursors. Conversely, those paving asphalt precursors from which a high quality paving asphalt cement may not be obtained are referred to hereinafter as “non-high quality paving asphalt precursors”. Similarly, those VTB and similar material from which a lower quality paving asphalt cement is obtained or which may be used as a lower quality paving asphalt cement comprise the low quality paving asphalt precursors. Non-high quality paving asphalt precursors include low quality paving asphalt precursors and non-paving asphalt precursors. RAHA OIL Bitumen Oxidized 90/10 is widely used as an anti-slip layer compound in the piling industry, for the manufacture of roofing felts, the roofing and waterproofing industries, for sound dampening felts and under carriage sealant in the automotive industry, electric cable joint protection, joint filling compound, carpet-backing, corrosion protection, acoustic panels, chemical, fuel, Manufacture of paints, sealant compound, and many others. Also used in sealing saw cuts and joints where expected movements are minimum. It is also used in the manufacturing of bituminous marine mastic for the oil & gas pipeline joints. Further, Oxidized Bitumen is used in the manufacture of bituminous marine mastic, which is required for the oil and gas pipeline joints. Oxidized Bitumen 90/10 is used across a wide variety of industries and applications: Oxidized Bitumen 90/10 offers several advantages for industrial and construction applications: COMPARED TO PAVING GRADE BITUMEN: Proper heating and handling are essential for optimum performance and safety: Follow the MSDS for detailed safety and handling instructions. Workers should wear protective masks, gloves, and goggles during application. The asphalt can be removed from equipment and tools with kerosene or gasoline. Care should be taken when heating Blown Bitumen 90/10 to avoid over heating. We offer Oxidized Bitumen 90/10 in a variety of packaging formats to meet project needs: All packaging options ensure safe transport and easy handling at the destination

For more information, please Contact our Sales Team. Dubai, UAE based supplier with global export capability Whether you need Oxidized Bitumen 90/10 for waterproofing, insulation, industrial coatings, or construction, Raha Oil delivers consistent performance from Dubai to your project location. Email: info@rahaoil.ae

OXIDIZED BITUMEN 90/10

BLOWN ASPHALT 90/10

APPLICATION OF BLOWN ASPHALT 90/10

CONSTRUCTION & INFRASTRUCTURE

INDUSTRIAL COATINGS

SPECIALIZED APPLICATIONS

KEY BENEFITS

TECHNICAL ADVANTAGES OF BLOWN ASPHALT 90/10

STORAGE AND HANDLING

HEALTH & SAFETY

PACKAGING & SUPPLY OPTIONS

Oxidized Bitumen 90/10

Oxidized Bitumen 90/10

TECHNICAL DATA SHEET OF BLOWN BITUMEN 90/10

BITUMEN 90/10 TEST METHOD UNIT SPECIFICATION

Specific gravity @ 25/25 °c ASTM D70 Kg/cm³ 1.05 approx

Penetration @ 25°c ASTM D5 mm/10 5-15

Softening point °c ASTM D36 °C 85-95

Ductility @ 25°c ASTM D113 cm 1.5 Min

Loss on heating(wt) % ASTM D6 wt % 0.2 max

Flashpoint °c ASTM D92 °C 250 min

Solubility is CS2(wt) % ASTM D4 wt % 99.5 max

Spot test A.A.S.H.O.T102 - Negative

WHY CHOOSE RAHA OIL?

CONTACT & REQUEST A QUOTE

Phone / WhatsApp: +971 4 566 4998 / +971 56 281 7292

Office: Burlington Tower, Business Bay, Dubai, UAE

Request technical datasheets (TDS), MSDS, pricing, or samples our sales team is ready to assist.