Bitumen in Drum, Jumbo and Bulk Packing

Bitumen in Drum, Jumbo and Bulk Packing

PACKAGING FOR BITUMEN

Given the highly viscous nature of bitumen, its packaging plays a crucial role, taking into account factors such as cost, environmental impact, storage, and shipping. Bitumen packaging is categorized into three main types: new steel drums, jumbo bags, and bulk. The selection of the most suitable packaging type depends on specifications, bitumen volume, and weight. For a more in-depth understanding of these packaging options, we encourage you to watch our comprehensive video on bitumen packages and explore this article.

BITUMEN DRUM PACKAGING

Bitumen in Drum Packing

Bitumen in Drum Packing

Drums are the preferred packaging choice for bitumen, ensuring safety and consistent quality. The specifications of these drums vary based on bitumen volume, height, thickness, and lid design. The body thickness of the drum is standardized at 6 mm. These steel drums are specifically designed for the transportation and packaging of liquids and pasty materials such as bitumen. While new steel drums are favored for bulk trade, it’s worth noting that they are comparatively more expensive than jumbo bags, mainly due to the higher cost of steel compared to plastic. There are four distinct types of drums, each with its own set of specifications:

HERE ARE THE SPECIFICATIONS FOR THIS WIDELY USED DRUM TYPE:

SPECIFICATION OF LONG NEW STEEL DRUM

Other Name Normal drum 180 kg

Material New Cold Rolled Steel

Height (mm) 980

Diameter (mm) 500

Body thickness (mm) 0.6

Top/Base thickness (mm) 0.6

Net weight (kg) ± 2.5 182

Gross weight (kg) ±2.5 192

Empty drum weight(kg) ±1 9.5

Lid (a removable cover on the top of a drum) 11

Color Black

Advantages Sufficiently leak proof when filled with hot bitumen

SPECIFICATION OF LONG NEW STEEL DRUM

Other Name Normal Drum 150 kg

Material New Cold Rolled Steel

Height (mm) 860

Diameter (mm) 500

Body thickness (mm) 0.6

Top/Base thickness (mm) 0.6

Net weight (kg) ± 2.5 150

Gross weight (kg) ±2.5 158

Empty drum weight(kg) ±1 8.5

Lid (a removable cover on the top of a drum) 11

Color Black

Advantages This kind of drums are leak proof when filled with hot bitumen

SPECIFICATION SHORT NEW STEEL DRUM (BIG LID)

Other Name Normal Drum 156 kg

Material New Cold Rolled Steel

Height (mm) 890

Diameter (mm) 500

Body thickness (mm) 0.6

Top/Base thickness (mm) 0.6

Net weight (kg) ± 2.5 156

Gross weight (kg) ±2.5 164

Empty drum weight(kg) ±1 8.5

Lid (a removable cover on the top of a drum) 17

Color Black

Advantages It has high resistance to leakage

LONG NEW STEEL DRUM 200 KG SPECIFICATIONS

Other Name Normal Drum 200 kg

Material New Cold Rolled Steel

Height (mm) 950

Diameter (mm) 500

Body thickness (mm) 0.6

Top/Base thickness (mm) 0.6

Net weight (kg) ± 2.5 210

Gross weight (kg) ±2.5 220

Empty drum weight(kg) ±1 10

Lid (a removable cover on the top of a drum) 11

Color Black

Advantages Resistant and anti-leak

BITUMEN JUMBO BAG PACKING

Bitumen in Jumbo Bag

Bitumen in Jumbo Bag

The jumbo bag, also known as bitu-plast, bitu-bag, polybag, or poly cube, is a large, flexible, multi-layer bag designed for high-quality and durable bitumen packaging. Recognized for its excellent resistance and ease of use, this type of polyethylene bag has gained popularity in various industries. Notably, many bitumen exporters have shifted from steel drums to jumbo bags due to their reasonable pricing and efficiency.

In comparison to drums, jumbo bags contribute to a reduction in bitumen waste by approximately 3 to 4%. While traditional drum discharge requires heating, the process is simplified with jumbo bags. To unload the bitumen from a jumbo bag, one simply needs to tear the outer layer and introduce the bag into the molten furnace along with the inner layer, eliminating the need for additional heating.

BITUMEN BULK PACKING

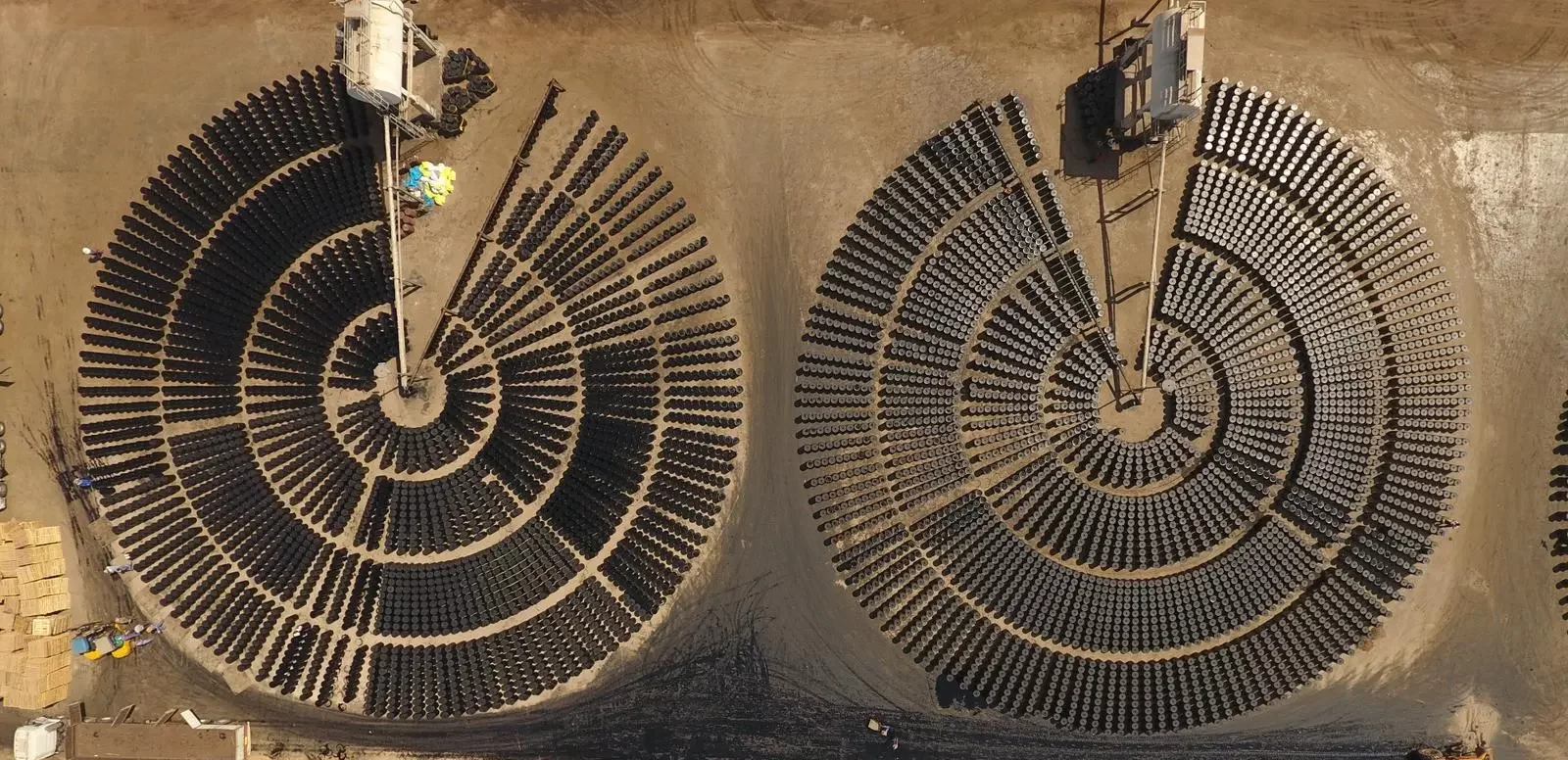

Bulk Bitumen

Bulk Bitumen

Bulk packaging involves the use of bitumen trucks for transporting the cargo from the refinery to the bulk vessel, known as the bitumen tanker, located at the port. Upon reaching the destination, another bitumen truck facilitates the pickup of the cargo for delivery to the construction site or designated bitumen warehouses. This packing method stands out for its cost-effectiveness, with pricing influenced by factors such as bulk capacity, loading duration, and exchange rate fluctuations. Overall, bulk packing is a financially advantageous option. For a detailed visual representation of the bulk shipment process, please refer to the image below: In addition to the aforementioned bitumen packaging methods, solid and dry bitumen, known as Oxidized Bitumen, is packaged using various approaches, including:

- Cartoon: Featuring a capacity of 25 kg and dimensions of 60*40*20 cm.

- Cartoon Pallet Shrink: Cartoons are positioned on a pallet and enveloped in shrink nylon; the pallet measures 110*110 cm.

- Polyamide: Bags with dimensions of 35*80, requiring drainage in cold water after being filled with oxidized bitumen.

- Polyester: A thin plastic layer characterized by high thermal tolerance, suitable for placement within a cartoon.

For further insights into the packing methods of oxidized bitumen, additional details can be found on the dedicated page.

ENVIROMENTAL IMPACT OF BITUMEN PAKAGING

(BULK BITUMEN, JUMBO BAG, NEW STEEL DRUM)

The heating process of bulk bitumen results in the emission of a significant amount of carbon, a greenhouse gas. Certain countries, such as Australia, prohibit the importation of bitumen in new steel drums due to concerns about potential pollution from bitumen residue in drums. However, when it comes to jumbo bags, there is a more positive environmental outlook.

Fortunately, jumbo bags, being a multi-layered packaging solution, are environmentally friendly. The inner layer is entirely consumable, and the outer layer is recyclable.

COST OF BITUMEN PACKAGING

GENERAL COMPARISON

When assessing the cost of bitumen packaging, it’s essential to consider various factors. While bulk bitumen might seem cost-effective, its transportation conditions can significantly impact the overall expense. Specialized tankers, vessels, and trucks are required for its transportation from origin to destination, resulting in high operating costs and maintenance expenses at the destination. Despite being the most affordable in terms of packing, the transportation and storage costs at the destination may outweigh the initial savings. Jumbo Bags and New Steel Drums offer a more cost-effective solution. Ordinary trucks can handle the delivery, and storage costs are significantly lower than bulk bitumen since standard storage facilities suffice. It’s worth noting that, due to the higher cost of steel compared to plastic, new steel drums may be slightly more expensive than jumbo bags.

For more information, please Contact our Sales Team.