What is Paraffin Wax?

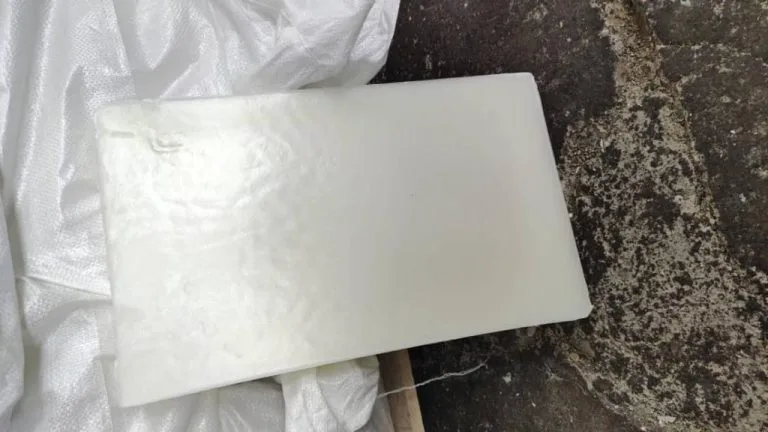

Paraffin wax, colorless or white, somewhat translucent, is a hard wax consisting of a mixture of solid straight-chain hydrocarbons ranging in melting point from about 48ᵒ to 66ᵒ C. It is obtained from petroleum by dewaxing light lubricating oil stocks. It is solid at room temperature and begins to melt above approximately 37 °C (99 °F). Common applications for paraffin wax include lubrication, electrical insulation, and candles, wax paper, polishes, cosmetics, and electrical insulators. It assists in extracting perfumes from flowers, forms a base for medical ointments, and supplies a waterproof coating for wood. In wood and paper matches, it helps to ignite the matchstick by supplying an easily vaporized hydrocarbon fuel. Fully refined paraffin wax of which oil content is maximum 0.5% and melting point 60/62 C. semi refined paraffin wax of which oil content is from 1% to 10% and melting point 58/60, 60/62 or 62/64 C, our paraffin wax colors differ from snow white transparent to cream depending its oil content and being heavy or light grade which is related to the melting point of the raw material used. Paraffin wax is a white or colorless soft solid derivable from petroleum, coal or oil shale, that consists of a mixture of hydrocarbonmolecules containing between twenty and forty carbon atoms. These waxes are categorized by oil content and the degree of refinement. The crudest versions fall into the slack wax category and contain between 7% to 20% oil. Next on the step of refinement are scale waxes containing between 0.5% to 7% oil that are called Semi Refined Paraffin Wax. The highest grade of refinement is the Fully Refined Paraffin Wax that has maximum 0.5% oil. Paraffin wax, colourless or white, somewhat translucent, hard wax consisting of a mixture of solid straight-chain hydrocarbons ranging in melting point from about 52° to 66° C (120° to 150° F). It is solid at room temperature and begins to melt above approximately 37 °C (99 °F) its boiling point is >370 °C (698 °F) Common applications for paraffin wax include lubrication, electrical insulation,rubber, and candles. It is distinct from kerosene, another petroleum product that is sometimes called paraffin. Praffin wax are semi refined and fully refined type. Semi refined is large used for making rubber product.

History of Paraffin Wax

Paraffin wax was first produced commercially in 1867, less than 10 years after the first petroleum well was drilled. It precipitates readily from petroleum on chilling. Technical progress has served only to make the separations and filtration more efficient and economical. Purification methods consist of chemical treatment, decolorization by adsorbents, and fractionation of the separated waxes into grades by distillation, recrystallization, or both. Crude oils differ widely in wax content. Synthetic paraffin wax was introduced commercially after World War II as one of the products obtained in the Fischer–Tropsch reaction, which converts coal gas to hydrocarbons. Snow-white and harder than petroleum paraffin wax, the synthetic product has a unique character and high purity that make it a suitable replacement for certain vegetable waxes and as a modifier for petroleum waxes and for some plastics, such as polyethylene.

Crude oil is the most important source of paraffin wax. Oil Refineries produce two main streams product category from crude oil; Fuels and lubricants. In the production of lubricants, refineries use atmospheric distillation residue as raw material and process it further until finished lubricant product is made. The byproduct of this process is called SLACK WAX, which is the raw material for paraffin wax manufactures in order to produce paraffin wax. Slack wax in general, is a mixture of Wax and Oil, which depend on the origin of material, can contain 25% oil content. The other and most advanced process of making paraffin wax is by Conversion of natural gas, gasified coal, and biomass to synthetic fuels. See the below process flow diagram. It is proven that commercially processing slack wax is more economical compared to the conversion of natural gas into paraffin wax. However, recent changes in oil and gas industry and environmental concerns shifted the view of manufacturers to use advanced manufacturing process and use natural gas as the feedstock. There are several methods which manufacturers and refineries can obtain paraffin wax from slack wax. The oldest method is Appling pressure on slack wax in order to separate oil from wax and filter the recovered wax. The finished product of this process is outdated in today’s world but still, local manufacturers use this process.

Paraffin Wax Production Process

The production process of paraffin wax involves several steps:

- Refining Crude Oil: Paraffin wax is derived from crude oil. The first step is to refine crude oil through a process called distillation. In this process, crude oil is heated in a distillation tower, and various components are separated based on their boiling points. Paraffin wax is obtained as a residue at the end of this process.

- Solvent Deoiling: After distillation, the obtained wax is still not pure. It contains impurities and oil. To remove these impurities and excess oil, the wax is mixed with a solvent (usually a solvent like heptane or hexane). This mixture is then cooled, causing the wax to crystallize, while the impurities remain dissolved in the solvent. The solidified wax is separated from the solvent and impurities.

- Hydrofinishing: The deoiled wax still contains some unwanted substances, such as unsaturated hydrocarbons, which need to be removed. Hydrofinishing is a process where the wax is treated with hydrogen under high temperature and pressure to remove these impurities.

- Straining and Filtration: The wax is then strained or filtered to remove any remaining particles or impurities.

- Cooling and Solidification: The purified wax is then allowed to cool and solidify into the desired forms, such as blocks, slabs, or pellets. The cooling rate can be controlled to produce different types of paraffin wax with varying properties.

The specific details of the production process can vary depending on the grade and quality of paraffin wax required. It’s essential to maintain strict quality control measures to ensure that the final product meets the desired specifications for its intended applications. Paraffin wax types There are different types of paraffin wax, which are classified based on their melting point and other properties. Some of the most common types of paraffin wax include: Fully refined paraffin wax: This type of paraffin wax is the purest and has the highest melting point. It is used in a variety of applications, including candles, cosmetics, and food packaging. Semi-refined paraffin wax: This type of paraffin wax is less pure than fully refined paraffin wax and has a lower melting point. It is often used in industrial applications, such as electrical insulation and lubricants. Microcrystalline paraffin wax: This type of paraffin wax has a very small crystal size and a high melting point. It is often used in food packaging and industrial applications.

Usage of Paraffin

Our state of the art refinery makes us able to source high quality semi-refined paraffin wax and fully refined paraffin wax with oil content in the ranges of 3-5 %, 1-2 %, and less than 1%, which can be used in various industries. Paraffin wax is the primary raw material utilized in the production of candles and is used in the manufacture of rubber and tires, chipboard, plastics, foodstuffs, food packaging, printing inks and paints, textiles, asphalt and many other products.

- It is used in candles, wax paper, polishes, cosmetics, and electrical insulators.

- It assists in extracting perfumes from flowers, forms a base for medical ointments, and supplies a waterproof coating for wood.

- In wood and paper matches, it helps to ignite the matchstick by supplying an easily vaporized hydrocarbon fuel.

Other Usage of Paraffin

- Bottles: to seal, dip the top of the bottle in melted wax.

- Irons: to keep them smooth, rub hot iron over a bar of wax wrapped in cloth.

- Drawers: to lubricate, rub a bar of wax over the sliders.

- Windows: to keep them opening and closing smoothly, run a bar of wax over the tracks.

- Zippers: to keep them from sticking, rub the teeth of the zipper with a bar of wax.

- Snow Shovels: to help the snow slide off the shovel, rub a bar of wax over a dry shovel.

- Toboggans: to lubricate, rub the skin with a bar of wax.

- Trash cans: to keep things from sticking, coat the inside with melted wax.

- Chocolate Making: for a shiny coat, add a little (food grade) wax to the melted chocolate.

- Hard Cheese: to keep it fresh, dip the exposed cheese in melted (food grade) wax.

- Handrails: to lubricate, rub the handrails with a bar of wax.

- Steel or Iron: to prevent oxidation; rub the surface with a bar of wax.

- Fruits and Vegetables: to keep fresh longer, dip the fruit or vegetables in melted (food grade) wax. This will slow down the moisture loss and keep them from spoiling.

- Candles: to make your own, there are several tutorials on the web for making your own candles.

- Hands & Feet: to soften, dip hands and feet into a low temperature wax bath. Wait 10-15 minutes then remove the wax.

- Crayons: to make your own, all you need is paraffin wax and some pigments.

Benefits of Paraffin Wax

Paraffin wax offers two significant benefits, which make it the obvious choice for the cosmetics industry.

Cosmetics (General): Petroleum waxes serve as safe base material, solvent or carrier to provide moisture barrier, modify viscosity, or solidify formulations.

Softens skin: Paraffin hydrates and coats skin making it softer and smoother. It also opens up the skin’s pores and increases blood circulation, which helps skin absorb moisture. Wax is a great ingredient for moisturizing skin cuticles and treating extremely dry skin. This makes it an important in gradient for the cosmetic industry.

Relieves pain: wax is also used as a pain treatment ingredient. Smoothing molten wax on to the pain spot encases the area, helping trap in heat to relax and soothe the surrounding tissues. Although it began being used to treat stiff joints and arthritis pains, therapists began using it all over the body for de-stressing and relaxing treatments.

Paraffin Wax Color

Paraffin Wax

Paraffin WaxNotice About Paraffin

Here are some additional things to keep in mind about paraffin wax

- PW is non-toxic and biodegradable.

- PW is insoluble in water, but soluble in ether, benzene, and certain esters.

- PW is unaffected by most common chemical reagents but burns readily.

- PW is a good insulator of heat and electricity.

- Avoid contact with hot PW, as it can cause burns.

- Use PW in a well-ventilated area.

- Keep PW away from open flames and other heat sources.

- Store PW in a cool, dry place.

Paraffin Wax Packing

Paraffin wax is typically packaged in various forms depending on its intended use.

Here are some common packaging options:

- Blocks or Slabs: Paraffin wax is often sold in the form of large blocks or slabs. These can be further cut or shaved into smaller pieces for specific applications, such as candle making.

- Pellets or Beads: In some cases, paraffin wax is processed into small pellets or beads, making it easier to measure and melt. This form is commonly used by candle makers and in some industrial applications.

- Bars or Sticks: For applications like sealing or wax-based crafts, paraffin wax can be molded into sticks or bars for convenient handling and application.

- Granules or Powder: In certain industrial settings, paraffin wax can be provided in the form of granules or even powder, particularly for specialized applications.

- Packaged Containers: Paraffin wax intended for cosmetic and spa treatments is often sold in containers such as jars or bags. These containers can vary in size to suit the needs of salons or individuals.

- Wrapped Sheets: Paraffin wax used for food preservation, like cheese or certain fruits, may come in the form of pre-wrapped sheets or rolls that can be easily applied to the food.

- Custom Packaging: Depending on the specific industry and application, there may be custom packaging options available to meet the requirements of the product.