What is Polyethylene Wax?

Polyethylene Wax is a type of polymer, or plastic, that is widely used in various applications. It is a synthetic material made from repeating units of the ethylene monomer. Polyethylene is known for its versatility, durability, and low cost. Polyethylene wax is obtained from ethylene through a process called polymerization.

Manufacturers modify the polymerization process to obtain a product of the desired quality. Due to its highly crystalline nature, this material has unique properties such as hardness at high temperatures and low solubility in a wide range of solvents. In this article, with the help of the Oil & Gas Market Analysis Team, we will discuss the properties and characteristics of this polyethylene polymer. PE Wax is one of the most important wax compounds used as an additive in various industries. This chemical compound is produced from the polymer polyethylene and has special properties that have made it a very popular and practical material in the industry.

Due to its special properties, PE is used in various industries such as the plastics industry, paints and varnishes, printing and packaging, car care and flooring industry, soap and hygiene products industry and candle making industry. This wax acts as a chemical agent resistant to heat, water, humidity and pressure and is typically used as an anti-adhesion, anti-scratch and surface properties improver.

Polyethylene Wax Grades

- Low-Density Polyethylene (LDPE): LDPE is flexible, lightweight, and used for items like plastic bags, squeezable bottles, and some types of packaging.

- High-Density Polyethylene (HDPE): HDPE is more rigid and is used in products like milk jugs, detergent bottles, and pipes.

- Linear Low-Density Polyethylene (LLDPE): LLDPE is a flexible plastic used in products like plastic wraps and trash bags.

Polyethylene is used in a wide range of applications due to its excellent chemical resistance, low moisture absorption, and ease of processing. It’s one of the most commonly used plastics in the world Polyethylene wax is a synthetic wax that is derived from polyethylene, a common plastic material.

Types of Polyethylene Wax

Low Density Polyethylene Wax

Low Density Polyethylene Wax is a type of polymer wax that has a lower density than other types of PE Wax. This property makes low density PE Wax used as an additive and auxiliary material in various industries.

Below are some of the applications of low density polyethylene wax:

Plastics Industries: Low Density PE Wax can be used as an auxiliary material in the production of plastic products. This wax can improve the surface properties of plastic products, such as increased gloss, smoothness, and better fiber drawing.

Printing Industries: Low Density PE Wax is used as an additive in the printing industry. This wax can add properties such as smoother ink flow, better fiber drawing, and improved lubrication to printed products.

Paint Industry: Low-density PE Wax can be used as an additive and colorant in the paint industry. This wax can add properties such as improved paint flow, better adhesion and increased gloss to paints and colorants.

Textile Industry: Low-density PE Wax can be used in the textile industry. This wax can improve the surface properties of fibers, such as reducing friction and improving fiber draw.

Wood and Furniture Industry: Low-density PE Wax can be used in the wood and furniture industry. This wax can be used as an auxiliary material in lubrication and improving the surface properties of wood products.

Food Industry: Low-density PE Wax can be used in some food industries as an auxiliary material. For example, it is used in food packaging, such as to seal the edges of bags or to improve the surface properties of food.

The use of low-density polyethylene wax in each specific industry is due to its specific properties and needs. In any case, before using any type of wax, it is best to consult with the product manufacturer or relevant experts to ensure that low-density polyethylene wax is suitable for your needs.

High Density Polyethylene Wax

High Density Polyethylene Wax is a type of polymer wax that has a higher density than other types of PE Wax. This wax is used in various industries due to its special properties and characteristics.

Below are some of the applications of high density polyethylene wax:

Paper Industries: High Density PE Wax is used as an auxiliary material in the paper industry. This wax can improve the surface properties of paper and prevent moisture from penetrating into the paper.

Printing Industries: High Density PE Wax is used as an additive in the printing industry. This wax can improve the surface properties of printed products, such as preventing ink from being absorbed by the printed surface and increasing gloss.

Plastics Industries: High Density PE Wax can be used as an auxiliary material in the production of plastic products. This wax can improve the surface properties and mechanical strength of plastic products.

Textile industry: High-density PE Wax can be used in the textile industry. This wax can improve the surface properties of fibers, such as reducing friction and improving fiber drawability.

Food industry: High-density PE Wax can be used in some food industries. This wax can be used as an auxiliary material in food packaging, in order to maintain freshness and reduce the penetration of moisture and oxygen into the package contents.

Oxidized Polyethylene Wax

Oxidized Polyethylene Wax is a type of wax that is produced from polyethylene as the main material and is formed in the process of oxidation of polyethylene. In this process, polyethylene reacts with oxygen and oxide functional groups are attached to the polymer chain.

Oxidized polyethylene wax has various properties and applications. For example:

Increase in surface properties: Oxidized polyethylene wax can improve the surface properties of various materials. This wax can act as an anti-scratch agent, reduce friction and reduce surface water absorption.

Use in the printing industry: Oxidized polyethylene wax is used as an additive in the printing industry. This wax can improve the surface properties of printed products, such as increasing gloss and preventing ink absorption by the printed surface.

Use in Plastics Industry: Oxidized polyethylene wax can be used in the production of plastic products. This wax can improve the surface properties and mechanical strength of plastic products and can also be used as an auxiliary material in injection, breakfast and extrusion processes.

Use in Paint and Resin Industries: Oxidized polyethylene wax can be used as an additive in the production of paints and resins. This wax can add anti-fouling, anti-scratch and surface property improving properties to the final products.

Use in Various Industries: Oxidized polyethylene wax may be used in various industries such as textile industries, leather industries, food industries and cosmetic industries as an auxiliary material.

The use of oxidized polyethylene wax varies depending on the specific needs of the industry and the type of product being produced. Before using this type of wax, it is best to consult with the product manufacturer or relevant experts to ensure that oxidized polyethylene wax is suitable for your needs.

Acid-modified Polyethylene Wax

Acid-Modified Polyethylene Wax is a type of wax produced using a chemical modification process with acid. In this process, PE Wax undergoes chemical changes using acid, which leads to changes in its properties and characteristics.

Acid-modified polyethylene wax can have various properties and applications. For example:

Use in printing industries: This type of wax can be used as an additive in the printing industry. By adding acid-modified PE Wax to printing inks, it provides better surface properties and lubrication for printing.

Use in paint industries: Acid-modified PE Wax can be used as an additive in the production of paints and resins. This wax can improve the surface properties and mechanical strength of the final products.

Use in Plastics Industry: Acid-modified PE Wax may be used as an auxiliary material in the production of plastic products. This wax can improve the surface properties, abrasion resistance and prevent adhesion of plastic products.

Use in Leather Industry: Acid-modified polyethylene wax can be used in the production of leather products as a filling agent and a moisture and water protector. This wax can add waterproof, moisture-proof and wear-resistant properties to leather.

Micronized Polyethylene Wax

Micronized Polyethylene Wax is a type of wax that is produced from polyethylene as the main material and then micronized. In the micronization process, PE Wax is divided into very fine sizes, so that its particle size is about 1 to 10 microns.

Micronized Polyethylene Wax has various properties and applications. For example:

Use in Printing Industries: Micronized PE Wax can be used as an additive in the printing industry. By adding this wax to printing inks, it provides better surface properties for printing and can prevent the absorption of ink by the printed surface.

Use in Paint Industries: Micronized PE Wax can be used as an additive in the production of paints and resins. This wax can improve anti-fouling properties, increase gloss and improve surface properties of the final products.

Use in Plastics Industry: Micronized PE Wax can be used in the production of plastic products as an auxiliary material. This wax can improve the surface properties and mechanical strength of plastic products and also reduce friction in plastic processing processes.

Use in Leather Industry: Micronized PE Wax may be used in the production of leather products as a filler and protector against moisture and water. This wax can add waterproof and moisture-proof properties to leather and also help improve abrasion resistance.

Polyethylene Emulsion Wax

Polyethylene emulsion wax is a type of wax that is produced as an emulsion in water. This type of wax consists of polyethylene particles that are mixed with water by emulsifying agents to create a stable emulsion.

Polyethylene emulsion wax has various properties and applications. For example:

Use in the paint industry: Polyethylene emulsion wax can be used as an additive in the production of paints and resins. This wax can improve the surface properties, mechanical strength and gloss of the final products.

Use in the printing industry: Polyethylene emulsion wax can be used as an additive in the printing industry. By adding this wax to printing inks, better surface properties are provided for printing and can prevent the absorption of ink by the printed surface.

Uses in Coatings: Polyethylene emulsion wax may be used in the production of protective and water- and moisture-resistant coatings. This wax can add water- and moisture-repellent properties to the surface of products and protect them from deterioration and damage caused by water and moisture.

Uses in Cosmetics: Polyethylene emulsion wax can be used in the production of cosmetic products such as moisturizers, lotions and skin creams. This wax can improve the emollient, protective and spreadability properties of the products.

Main Uses Of Polyethylene Wax

Polyethylene wax is an adhesive, waterproof, and friction-reducing agent used in various industries.

Some of the uses of polyethylene wax include:

Printing industries: PE Wax is used as an additive in printing inks. This wax can add better surface properties to printing and prevent ink from being absorbed by the printed surface.

Packaging industries: PE Wax is used in the production of packaging films and layers. This wax can improve waterproof properties, prevent air penetration, and maintain the freshness of products.

Plastics industries: PE Wax is used as an auxiliary material in the production of plastic products. This wax can improve surface properties, mechanical strength, and friction-reducing agents in plastic processing processes.

Paint and resin industries: PE Wax can be used as an additive in the production of paints and resins. This wax can improve the gloss, anti-fouling and surface properties of products.

Leather industry: PE Wax is used in the production of leather products such as shoes, bags and belts. This wax can improve the waterproof and moisture-proof properties of leather and protect it from abrasion and damage caused by moisture and water.

Cosmetics industry: Polyethylene wax can be used in the production of cosmetic products such as moisturizers, lotions and skin creams. This wax can improve the softening, protective and spreadability properties of products.

Factors For Choosing The Right Polyethylene Wax

Choosing the right type of polyethylene wax depends on your specific needs and use. Below, I will mention some types of PE Wax and their applications:

Liquid polyethylene wax: This type of wax is used in the printing, packaging, and dyeing industries. If you need to make the surface of your product shiny and waterproof, this type of wax is suitable.

Polyethylene wax paste: This type of wax is used in the leather, shoe, and cosmetic industries. If you need to soften your product, add waterproof and moisture-proof properties to it, or add shine to the surface, this type of wax is suitable.

Powdered polyethylene wax: This type of wax is used in the plastic and resin industries. If you need to improve the anti-fouling properties and improve the surface properties of your plastic products, this type of wax is suitable.

Polyethylene Wax Production Process

The polyethylene wax production process generally includes the following steps:

Polymerization: This step involves the production of polyethylene polymer. Polyethylene is a thermoplastic polymer produced from ethylene monomer. In this step, the ethylene monomer is subjected to reaction conditions to convert into long polymer chains.

Addition of antioxidant agents: To prevent oxidation and rusting of polyethylene during the production and storage process, antioxidant agents are added to the polymer. These agents prevent the polymer from being destroyed by oxygen in the air.

Addition of additives: In order to improve the properties of polyethylene, various additives are added to it. These materials can include colorants, sunscreens, heat and fire resistant materials, impact resistant materials, etc. Adding these materials to polyethylene can change its mechanical, waterproof, thermal and appearance properties.

Forming process: In this stage, polyethylene is shaped into the required shape. This process can include injection, pressing, blowing, casting or other processes, by which polyethylene is produced in the form of parts, sheets, pipes, films, etc.

Final processing: In this stage, polyethylene parts undergo final processes such as cutting, bending, welding and cleaning. The aim of this stage is to obtain a final product with the desired accuracy and quality.

Since polyethylene wax is used for different applications, its production process may vary based on the specific needs of each application and may have different additives and forming methods. In any case, the PE Wax production process begins with the production of polyethylene polymer from ethylene monomer and is completed by adding additives and shaping the final product.

Packing

PE Wax is typically packaged to ensure ease of handling, transportation, and protection from contamination or moisture. Common packaging options include:

Bags:

- 25 kg Bags: Often made of kraft paper or polyethylene-lined plastic to protect against moisture and environmental exposure.

- Suitable for smaller-scale industries and easier handling.

Super sacks / jumbo bags:

- 500 kg to 1000 kg: Ideal for bulk transportation and industrial use.

- Made from durable woven polypropylene for heavy loads.

Drum:

- Steel or plastic drums are used for pastilles or liquid forms, typically with a 200-liter capacity.

- Provides excellent protection against environmental exposure.

Bulk packaging:

- For very large volumes, PE Wax is transported in bulk containers or tanker trucks for molten wax.

LABELING: All packaging is labeled with essential details like grade, weight, batch number, safety instructions, and manufacturer information. This ensures traceability and safe handling.

Technical Data Sheet of Polyethylene Wax

Common Grades:

Grade Softening Point (°C) Penetration Index (D1321) Flash Point (°C) Viscosity @140°C (Cp) Appearance/Characteristics Application

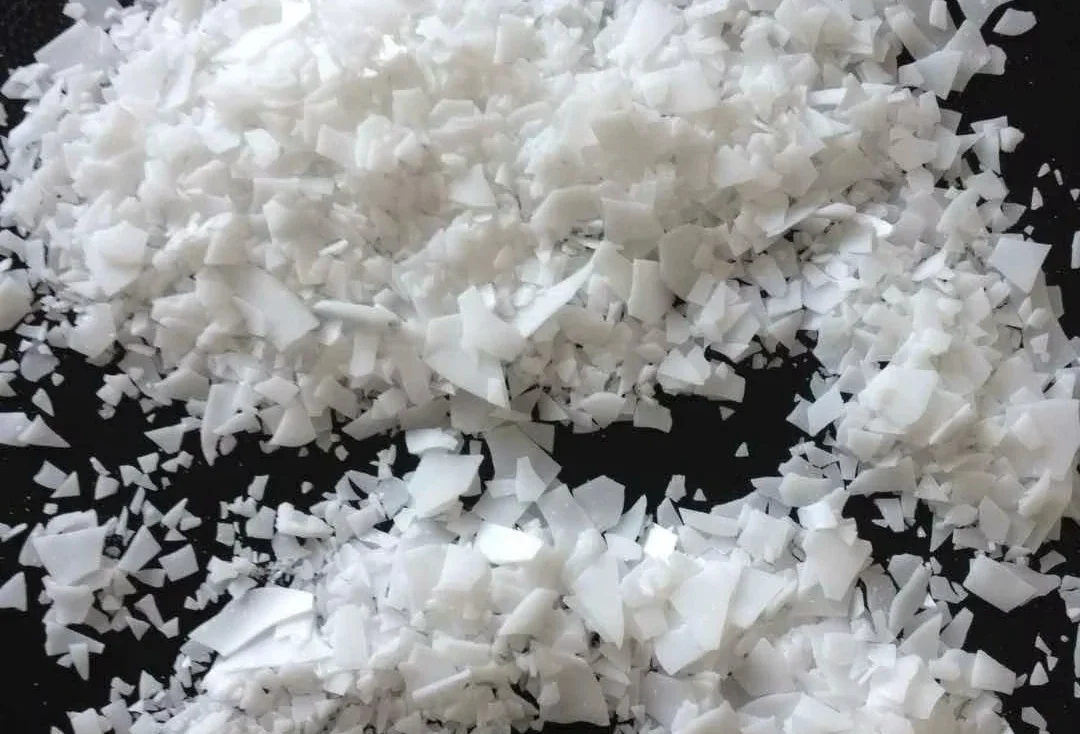

PE WAX 1370 85-90 20-30 < 130 10-40 Snow white flakes, free of black spots PVC pipes & panel, filler masterbatch

PE Wax 1380 100-105 5-8 < 140 10-20 Dry and snow-white flakes, free of black spots PVC, high quality filler & color masterbatch

PE wax 1385 110-115 10-15 < 140 100-150 White flakes, free of black spots Filler masterbatch

PE WAX 1390 90-95 15-20 < 140 10-20 Snow white flakes, free of black spots PVC pipes and panel, filler masterbatch

HD WAX 1200F 105-110 3-4 > 180 20-40 Super dry snow white flakes, high softening point. Good hardness, non-toxic, good thermal stability, low volatility Hot melt adhesive, high quality PVC stabilizer, high quality filler & color masterbatch

HD WAX 1205 Bead 105-110 3-4 > 200 20-50 Super dry white beads, high softening point. Good hardness, non-toxic, good thermal stability, low volatility Hot melt, high quality PVC stabilizer, high quality filler & color masterbatch

HD WAX 1105F Flake 105-110 3-6 > 170 20-50 Super dry snow white, high softening point. Good hardness, non-toxic, good thermal stability, low volatility Hot melt, high quality PVC stabilizer, high quality filler & color masterbatch

Supplier of Polyethylene Wax

We are a supplier and exporter specializing in Polyethylene Wax. With years of experience in the industry, we have built a reputation for delivering high-quality products to our clients across Turkey, Romania, Bulgaria, Serbia, Ukraine, Bosnia, Poland, Greece, Oman, Iraq, Pakistan, India, Taiwan, Thailand, and Vietnam. However, our team will assist at every step to ensure a smooth and timely supply. (Contact Us)