Bitumen Penetration 200/300

Bitumen Penetration 200/300

BITUMEN PENETRATION 200/300

Bitumen Penetration 200/300 is mainly used in the manufacture of hot mix asphalt for bases and wearing courses. Penetration Grade Bitumen is a standard bitumen usually used as a Paving Grade Bitumen essential for road construction and for the production of asphalt pavements with superior properties, and it’s very important once it bounds the aggregates and creates a unique cohesion and stability to the bituminous mix. In general, Bitumen Penetration Grade 200/300 is used as a Paving Grade Bitumen suitable for road construction and for the production of asphalt pavements with superior properties, especially in road and airport constructions and other similar applications. It is a standard Penetration Grade of Bitumen ASTM D946-09. Hot mix asphalt for bases and wearing courses is mostly made using this grade of bitumen. The Vacuum Residue used to make Bitumen Penetration Grade 200/300 is blown by hot air in the Biturox Blowing Unit; the completely automated process produces a consistent, homogenous end product.

ASPHALT 200/300 PROPERTIES

Pure petroleum grade bitumen, created from a vacuum bottom by the passage of hot air, is what makes up the penetration grade Bitumen Penetration Grade 200/300 that our company supplies. After being cracked and the hydrocarbons were removed, the bitumen that our company supplies is made from the leftover crude oil. The softening point of penetration grade bitumen 200/300 is between 32 and 37 C, and its penetration ranges from 200 to 300 desi-millimeters. The thermoplastic feature of the penetration grade bitumen 200/300 is similar to that of a synthetic resin substance in that it softens when heated and hardens when cooled.

USES OF BITUMEN PENETARTION 200/300

The main common usage of this product is in road construction and for the production of asphalt pavements with superior properties. this grade of bitumen is mainly used in the manufacture of hot mix asphalt for basis and wearing courses.

- Road Construction: Bitumen 200/300 is commonly used in road construction as a binder in asphalt mixes. It provides durability and stability to road surfaces, contributing to their overall strength.

- Asphalt Emulsions: It can be used to produce asphalt emulsions, which are water-based bitumen dispersions. Asphalt emulsions are employed for various road maintenance activities, including chip seals, surface treatments, and tack coats.

- Roofing: Bitumen 200/300 is utilized in the roofing industry for manufacturing roofing felt, shingles, and other roofing materials. Bitumen-based roofing materials offer waterproofing and weatherproofing properties.

- Waterproofing: The waterproofing industry uses Bitumen 200/300 for applications such as foundation and basement waterproofing. It forms a durable and impermeable layer, preventing water penetration.

- Pipe Coating: In the oil and gas sector, Bitumen 200/300 is applied as a coating for pipes to provide corrosion resistance and insulation. This protective coating helps safeguard pipelines from environmental factors.

- Pavement Sealants: Bitumen 200/300 can be used in pavement sealants applied to existing asphalt surfaces. These sealants enhance the longevity of pavements and protect against weathering and aging.

- Adhesives and Binders: Bitumen 200/300 serves as a crucial component in the production of adhesives and binders. It imparts bonding strength and acts as a binding agent in various industrial applications.

- Soundproofing: Bitumen 200/300 is employed in the manufacturing of soundproofing materials for buildings and infrastructure. Its ability to absorb sound contributes to reducing noise transmission.

- Construction Mastics: Bitumen 200/300 may be used in construction mastics, which are flexible, adhesive compounds applied to seal joints and cracks in construction projects.

- Bridge Deck Waterproofing: Bitumen 200/300 is applied in the waterproofing of bridge decks to protect the underlying structure from water ingress and enhance the longevity of the bridge.

The specific use of Bitumen 200/300 can vary based on regional specifications, climate conditions, and project requirements. It is important to consider the penetration value, which influences the bitumen’s hardness and consistency, affecting its suitability for different applications.

APPLICATION OF ASPHALT GRADE 200/300

This grade of bitumen is also mainly used in the manufacture of hot mix asphalt. also, Bitumen is suitable for road construction and repair for asphalt pavements with superior properties. Bitumen is used for hot mixed asphalt because of the properties of very strong viscosity compared to other grades. Also used in specialized applications like airport runways and also in very heavy traffic volume roads in coastal cities in the country.

THE 4 MAJOR TEST OF ASPHALT 200/300

1.PENETRATION TEST: It measures the hardness or softness of bitumen by measuring the depth in tenths of a millimeter to which a standard loaded needle will penetrate vertically in 5 seconds. BIS had standardised the equipment and test procedure. A grade of 200/300 bitumen means the penetration value is in the range 200 to 300 at standard test conditions. In hot climates, a lower penetration grade is preferred.

2.SOFTENING POINT TEST: Softening point denotes the temperature at which the bitumen attains a particular degree of softening under the specifications of test. The test is conducted by using Ring and Ball apparatus. Also Temperature is noted when the softened bitumen touches the metal plate which is at a specified distance below. Generally, higher softening point indicates lower temperature susceptibility and is preferred in hot climates. Figure 0.1 shows Softening Point test setup.

3.DUCTILITY TEST: Ductility is the property of bitumen that permits it to undergo great deformation or elongation. Ductility is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking.

4.VISCOSITY TEST: Viscosity denotes the fluid property of the bituminous material and it is a measure of resistance to flow. At the application temperature, this characteristic greatly influences the strength of resulting paving mixes. Low or high viscosity during compaction or mixing has been observed to result in lower stability values.

GUARANTY AND SAFETY OF ASPHALT 200/300

RAHA OIL guaranty the quality of Bitumen penetration grade 200/300 with the arrangement of the international inspectors to check the quality and quantity of the bitumen penetration grade 200/300 during the loading to the vessel and controlling the production by QC by batch test report before shipping. our Company guarantees the quality to meet with ASTM.

PACKING OF BITUMEN 200/300

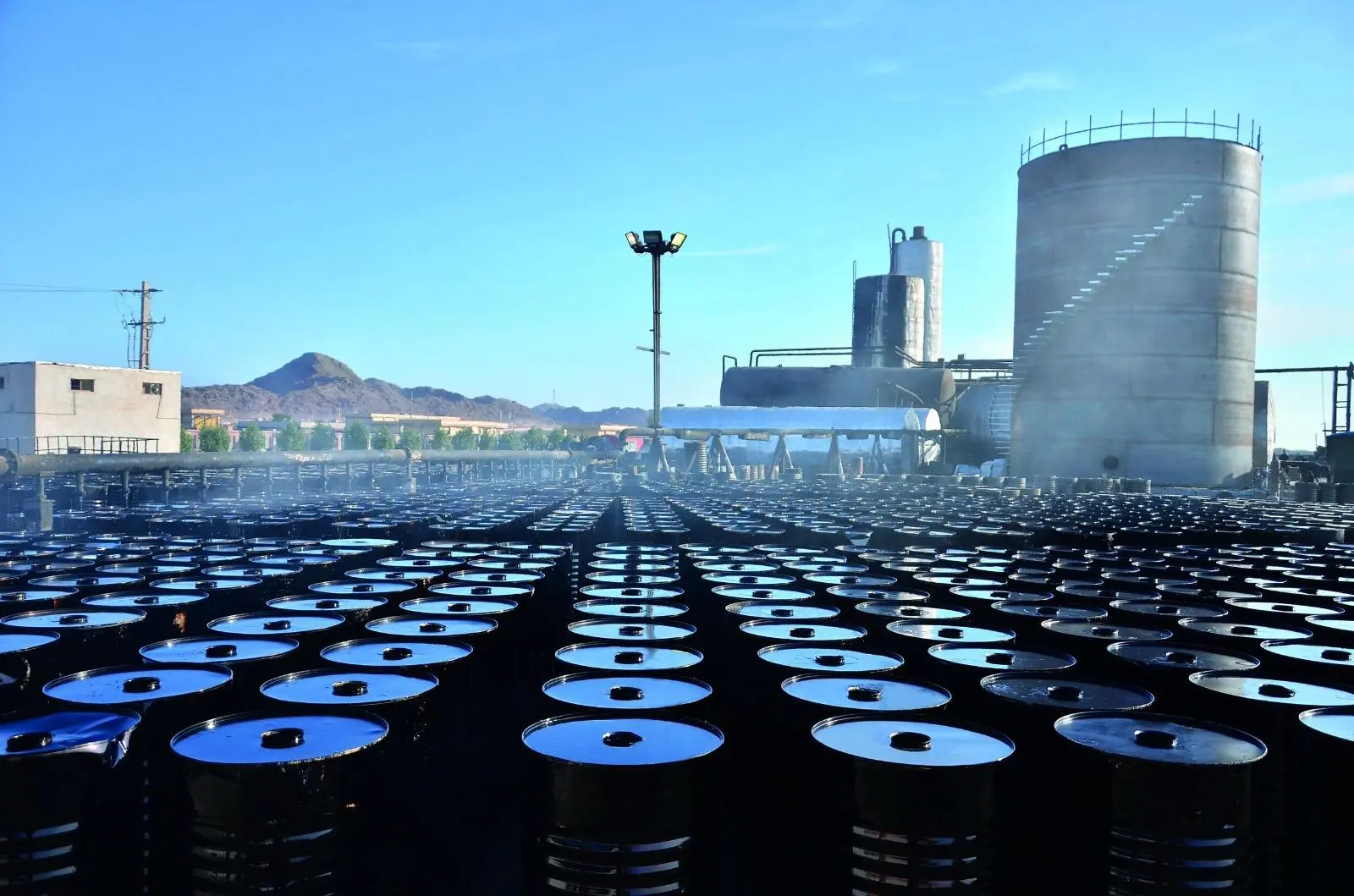

Bitumen’s packaging is a real concern especially if it’s meant to be exported, the better and safer packaging, guarantees the better delivery of the cargo. There are several different ways to package the bitumen which can vary depending on the tonnage, type, and grade of the bitumen- as mentioned before, different grades of bitumen have different levels of stiffness and viscosity- so the grade also plays an important role in choosing a suitable packaging. Bitumen Penetration 200/300 is commonly packed in new steel drums, 150, 180 & 220 Kg barrels and Jumbo Bags or 300 Kg Bitubag.

BITUMEN 200/300 IN 180 KG NEW STEEL DRUM:

Loading 110 Drum in 20 ft

Loading 110 Drum in 20 ft

BITUMEN 200/300 IN BULK IN TANKER:

Loading 24 – 25 MT in Tanker Truck

BITUMEN 200/300 BULK IN VESSEL:

Loading 2000 to 20,000 MT in Bitumen Carrier

Loading 2000 to 20,000 MT in Bitumen Carrier

TECHNICAL DATA SHEET OF PENETRATION 200/300

BITUMEN 200/300 TEST METHOD UNIT SPECIFICATION

Specific gravity @ 25/25 °c ASTM D70 Kg/cm³ 990/1040

Penetration @ 25°c ASTM D5 mm/10 200-300

Softening point °c ASTM D36 °C 32 min

Ductility @ 25°c ASTM D113 cm 100 min

Loss on heating(wt) % ASTM D6 wt % 1 max

Drop in penetration after heating % ASTM D5-D6 % 37 max

Flashpoint °c ASTM D92 °C 177 min

Solubility is CS2(wt) % ASTM D4 wt % 99 max

Spot test A.A.S.H.O.T 102 - Negative

For more information, please Contact our Sales Team.