Oxidized Bitumen 75/25

Oxidized Bitumen 75/25

DESCRIPTION OF OXIDIZED BITUMEN 75/25

Oxidized Bitumen 75/25 is a semi-solid grade of pure petroleum bitumen manufactured by air-blowing through an asphalt flux. Special physical properties of its grade can be used in different applications in the construction business. Oxidized Bitumen 75/25 is based on petroleum bitumen which is made by oxidized bitumen 60/70 by very hot air. The numbers relate to the midpoint of the material’s softening point and penetration respectively. The softening point value is the degrees Centigrade measured by the Ring and Ball method as determined by ASTM D36. The penetration value is 1/10 mm as determined by IP49 or ASTM D5. Oxidized bitumen has a higher softening point than viscosity grade and penetration bitumen. Consequently, oxidized bitumen is less susceptible than penetration bitumen and viscosity bitumen to temperature changes. Oxidized Asphalt is a solid or semi-black solid material and gradually liquid when heated, oxidized asphalt is the predominant content of bitumen, asphalt, molten (oils), and aromatic resins. The oxidized asphalt or blown asphalt is produced in different softening points and penetration. Our sales team is committed who understanding your requirements due to many years of experience in supplying bitumen products. If you are more interested in product information or need to place an order contact or inquire about our Sales team.

APPLICATION OF OXIDISED ASPHALT 75/25

Oxidized Bitumen uses in the chemical, fuel, lacquers, varnishes, paint paper-pulp-board, textile processing, road construction, pavement, civil works, roofing, construction industries; sealing and insulating buildings, adhesive, crack seal and repairmen, construction materials additive, dust-binding, insulating and impregnating agent, make rubber and plastic products. The asphalt R 75/25 products are for paving. also used in asphalt-based paints for corrosion protection of metals, in lining public works structures, adhesives in electrical laminates, base for synthetic turf; typical uses for oxidized bitumen 75/25 used also for water-proof application and corrosion resistance for pipe coating, Portland cement pavement, hydraulic applications, paint manufacturing, caulking, mastics, and damp proofing. Blown bitumen R 75/25 is using insulation and isolation bitumen membrane sheet. Also, Car undercoating Automobile industry is specially required for Blown Asphalt. Vehicle undercoating material is based on Bitumen. Bitumen provides excellent waterproof, dust proof and noise proof for automobile undercoating. Notice: The oxidized bitumen should be heated double temperature against the softening point to be able to have flow and viscosity. Road construction, hydropower projects, roofing, flooring, mastics, the oil and gas sectors, and electrical applications are just a few of the uses for oxidized bitumen 75/25.

Roads: Oxidized bitumen 75/25 is suitable for paving, constructing, and maintaining roads. It can be added to asphalt for parking lots, railways, highways, and other surfaces.

Hydro projects: A substance called oxidized bitumen 75/25 is used to line canals. This kind of bitumen can be utilized for further hydro projects, including constructing embankments and dams, hydraulic structures, protecting dam linings, and stabilizing sand.

Roofing: In roofing felts, shingle roofs, damp-proof coating compositions, carriage roofing compounds, liquid roof coatings, and plastic cements, oxidized bitumen 75/25 is used. It is often the best solution for waterproofing roofs.

Flooring: One of the main uses for oxidized bitumen 75/25 is flooring. Acid- and alkali-resistant bitumen mastic can be used to stop corrosion on the surface of chemical plants, fertilizer plants, steel factories, and other facilities. Additionally, it has the ability to restore parquet floors.

Oil and gas industry: To prevent pipeline corrosion and rust, oxidized bitumen 75/25 is often used in addition to cutback bitumen MC30. Bitumen 75/25 is used as a laminated board adhesive in the electrical industry. The ability to seal electrical junction boxes is present. It is used in cables, lithium-ion batteries, and the cable industry.

USES OF OXIDIZED BITUMEN 75/25

Bitumen is suitable to be used in the chemical, raw material for bitumen coat, paper-pulp-board, textile processing, pavement, crack seal and repairmen, civil works, bitumen coat for piping, roofing, construction industries; sealing and insulating buildings, adhesive, construction materials additive, road construction, dust-binding, insulating and impregnating agent, isolation bitumen membrane sheet, make rubber and plastic products. typical uses for bitumen 90/40 include roofing, pipe coating, hydraulic applications, 75/25 is mainly used in paint manufacturing and coating in the hot areas.

ADVANTAGES OF BLOWN ASPHALT 75/25

- Durability

- Flexibility

- Water Resistant

- Chemical Stability

STORAGE AND HANDLING OF OXIDIZED BITUMEN 75/25

Blown asphalt 75/25 is best up to 10 years from the day it was manufactured. It is suggested for the higher time of warehouse keeping to keep the bitumen under shelter and out of the rain and sunshine.

HEALTH & SAFETY

Workers should wear protective masks, gloves, and goggles during application. The asphalt can be removed from equipment and tools with kerosene or gasoline.

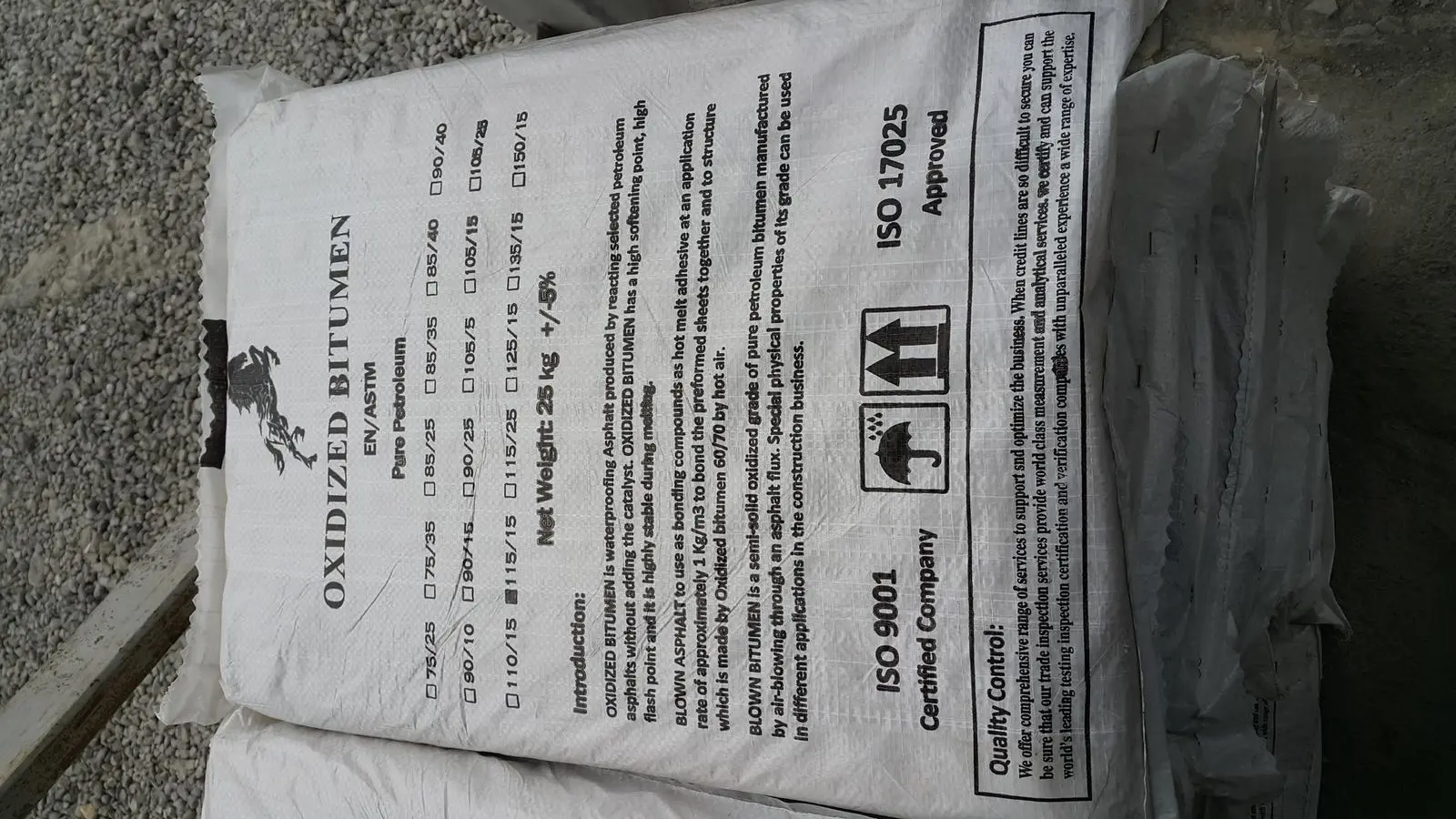

PACKING OF OXIDIZED BITUMEN 75/25

Oxidized Bitumen 75/25

Oxidized Bitumen 75/25

Blown Asphalt 75/25 in various packing, including bitumen 75/25 is available in 20 & 50 Kg Kraft Paper Bags 25 Kg Carton box & 150, 180, 200 Kg Steel Drums:

25 KG CARTON BOX

25 KG MOLD PACKING: It is most expensive packing since there is mold on and with same mold we can ship out. The mold is carton and at destination you can remove the mold easily.

25 KG POLYAMIDE BAG: It is heat resistance bag and filling directly in water to cool down fast. It is firstly use not possible to take out the Polyamide from the bitumen and then use.

25 KG CRAFT BAG: Craft bag is recycle packing and inside is special material to prevent sticking the bitumen to bag. This grade also possible to load on pallet or without pallet for customer.

TECHNICAL DATA SHEET OF OXIDIZED BITUMEN 75/25

BITUMEN 75/25 TEST METHOD UNIT SPECIFICATION

Specific gravity @ 25/25 °c ASTM D70 Kg/cm³ 1.05 approx

Penetration @ 25°c ASTM D5 mm/10 20-30

Softening point °c ASTM D36 °C 70-80

Loss on heating(wt) % ASTM D6 wt % 0.2 max

Flashpoint °c ASTM D92 °C 250 min

Solubility is CS2(wt) % ASTM D4 wt % 99.5 max

Spot test A.A.S.H.O.T 102 - Negative

For more information, please Contact our Sales Team.