Oxidized Bitumen 85/40

Oxidized Bitumen 85/40

DESCRIPTION OF OXIDIZED BITUMEN 85/40

Oxidized Bitumen 85/40 (also known as blown asphalt 85/40 and blown bitumen 85/40) is semi solid grade of pure petroleum bitumen manufactured by air-blowing through an asphalt flux. Oxidized bitumen 85/40 is based on petroleum bitumen which is made by blowing grade BITUMEN 60/70 bitumen by hot air. The numbers 85/40 relate to the midpoint of the material’s softening point and penetration respectively. The softening point value is the degrees Centigrade measured by the Ring and Ball method as determined by ASTM D36. The penetration value is in 1/10 mm as determined by IP49 or ASTM D5.

USES OF OXIDIZED ASPHALT 85/40

Oxidized bitumen 85/40 is used in the chemical, fuel, paints, lacquers, varnishes, paper-pulp-board, textile processing, road construction, pavement, crack seals and repairs, civil works, roofing, construction industries; sealing and insulating buildings, adhesive, construction materials additive, dust-binding, insulating and impregnating agent, and also to manufacture rubber and plastic products. Oxidized bitumen 85/40 products are also used in asphalt-based paints for corrosion protection of metals, in lining public works structures, adhesives in electrical laminates, base for synthetic turf. Typical uses for oxidized bitumen 85/40 are for water-proof application and corrosion resistance for pipe coating, Portland cement pavement, hydraulic applications, paint manufacturing, caulking, mastics, and damp proofing. This grade of bitumen can be used for insulation and isolation in bitumen membrane sheets. It is also used in the automobile industry for car undercoating as it is proven to be an excellent water-proofing, dust proofing and also noise proofing material.

APPLICATION OF OXIDIZED BITUMEN 85/40

Oxidized Bitumen 85/40 is a dark industrial bitumen. Petroleum residue modified by the oxidation process. In addition, Oxidized Bitumen is produced by passing air through bitumen under controlled temperature state. Its stability ranges from highly viscous to solid. Oxidized Bitumen grade has technical advantages such as durability, flexibility, water resistant and chemical stability. There is also the different grade of oxidized bitumen. The Oxidised Bitumen 85/40 should be heated double temperature against the softening point to be able to have flow and viscosity.

TECHNICAL ADVANTAGES OF BITUMEN 85/40

- Durability

- Flexibility

- Water Resistant

- Chemical Stability

COMPARED TO PAVING GRADE BITUMEN:

- Reduced temperature susceptibility

- Exhibits a more ‘solid’ nature at ambient temperatures

- High penetration index

ADVANTAGES OF BLOWN BITUMEN 85/40

- High Purity Oxidized Bitumen (Oxidised Bitumen) without Using Gilsonite and any other impurities

- Excellent and permanent adhesive

- Low water absorption

- Chemically stable

- Flexibility

- Impact resistant

- High Resistant to soil stress

- High Resistant to cold stress High electrical resistance Quality assured manufacture.

- Conforms to ASTM standards with regards to softening point and penetration.

- Competitive and fair price Prompt and on time Delivery

- Third party Inspection by Customer request

RECOMMNDATIONS FOR HANDLING/ STORAGE

Heating of packaged bitumen is a critical phase in most of the final uses. Typically, the packaged material is heated and melted in boilers out on site. However, control at the heating phase is very important in terms of health and safety as well as in maintaining the quality of the product. Note must be taken of the maximum safe handling temperature of 230 C and this should not be abused. Bitumen is a poor conductor of heat, consequently, control of the heating phase is of paramount importance. The Oxidized Bitumen material should be broken up prior to placement in the boiler. This exposes a larger surface area to the heat and encourages a more even heating regime. Without the larger exposed surface area, aggressive heating at the base and sides of the boiler may well result in localized overheating, altering the characteristics of the modified bitumen and potentially causing thermal cracking of the bitumen, creating the release of low lash vapors. The flash point of the oxidized bitumen then becomes irrelevant; as these low flash vapors determine the fire risk. Melted bitumen should not be left in the boiler and reheated from cold, as there is then a high potential for localized overheating around the heating area (lack of convection means poor heat transfer) and potential development of a pressurized pocket of low flash vapors. Be aware of the placement of any temperature monitoring or control devices. As a result of the poor thermal conductivity of the bitumen, a thermometer in the bitumen some distance from the heat source could read significantly different (even hundreds of degrees) from the true temperature of the bitumen near the heat source.

HEALTH & SAFETY

Workers should wear protective masks, gloves, and goggles during application. The asphalt can be removed from equipment and tools with kerosene or gasoline. Care should be taken when heating Oxidized Bitumen 85/40 to avoid overheating. For Health and Safety information, please make reference to the relevant MSDS.

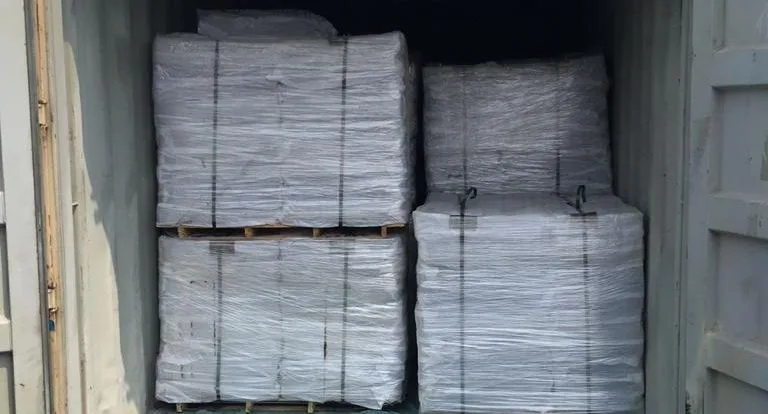

PACKING DENSITY OF BLOWN ASPHALT 85/40

RAHA OIL is the manufacturer of Oxidized Bitumen 85/40 in various packing, including bitumen 85/40 is available in 20 & 50 kg Kraft Paper Bags / Poly Amide Bags, 25 kg Carton box and 150, 180, 200kg Steel Drums. In addition, oxidized bitumen packing also palletize, 40 bags can stack on the pallet. 20 pallet can load to the 20ft container.

- Meltable Polyamide Bags (20KG) (25 Kg)

- Carton Box (20KG) (25 Kg) (40kg)

- Kraft Bags (20KG) (25 Kg) (40kg)

- Blocks (20KG) (25 Kg) (40kg)

- Drums (20KG) (25 Kg)

TECHNICAL DATA SHEET OF OXIDIZED BITUMEN 85/40

BITUMEN 85/40 TEST METHOD UNIT SPECIFICATION

Specific gravity @ 25/25 °c ASTM D70 Kg/cm³ 1.05 approx

Penetration @ 25°c ASTM D5 mm/10 35-40

Softening point °c ASTM D36 °C 80-90

Ductility @ 25°c ASTM D113 cm 3

Loss on heating(wt) % ASTM D6 wt % 0.2 max

Flashpoint °c ASTM D92 °C 260 min

Solubility is CS2(wt) % ASTM D4 wt % 99 max

Spot test A.A.S.H.O.T102 - Negative

For more information, please Contact our Sales Team.