Oxidized Bitumen 150/5

Oxidized Bitumen 150/5

DESCRIPTION OF OXIDIZED BITUMEN 150/5

Oxidized Bitumen 150/5 (also known as Blown Bitumen 150/5) which goes by the name R150/5 and has a high needle penetration and a high softening point (equivalent to 150), is also known as R150/5 (equal to 5 desi-millimeter). According to this information, Blown Bitumen 150/5 is one of the extremely hard grades of the Oxidized category. It is made by combining very hot air with pure Bitumen Penetration 60/70 as input for a reactor. This results in the production of a very hard grade. R150/5 was accomplished by directing very hot air through unadulterated bitumen in an environment where the temperature and pressure were strictly controlled. It is an international testing procedure, and its datasheet is based on standards established by the ASTM. ASTM D36 and ASTM D5 are the standards that are used to determine the softening point and the penetration degree, respectively, according to the standard that was specified.

Oxidized Bitumen 150/5 is the semi-solid oxidized grade of pure petroleum bitumen categorized in polycyclic aromatic hydrocarbons and is normally used for different purposes in the construction business. Bitumen 150/5 is based on petroleum bitumen which is made by blowing Bitumen 60/70 by hot air. This type of bitumen is hard and breakable. Oxidized bitumen 150/5 is the semi-solid oxidized grade of petroleum bitumen categorized in polycyclic aromatic hydrocarbons and is normally used for different purposes in the construction industries. Oxidized Bitumen 150/5 should be heated at double temperature (200ᵒ-300ᵒC) against the softening point to be able to have flow and viscosity. Normally heating of such hard oxidized bitumen should be arranged via hot oil by circulation inside of the isolated jacket. Bitumen oxide 150/5 from penetration grade bitumen, which is blown by hot air in a controlled process until the desired specification is reached. Oxidized bitumen 150/5 can be supplied in any grade and is designated by two numbers to indicate the softening point and penetration ranges. The oxidized bitumen 150/5 means the softening point is 150°c and penetration is 15 desi millimeters produced in compliance and conformity with ASTM standards.

USES OF OXIDIZED BITUMEN 150/5

Oxidized bitumen 150/5 uses in the chemical, raw material for bitumen coat, lacquers, varnishes, paper-pulp-board, textile processing, pavement ,crack seal and repairmen, civil works, bitumen coat for piping, roofing, construction industries; sealing and insulating buildings, adhesive, construction materials additive, road construction, dust-binding, insulating and impregnating agent, isolation bitumen membrane sheet, make rubber and plastic products. bitumen 150/5 products are for paving, roofing; also used in asphalt-based paints for corrosion protection of metals, in lining public works structures, adhesives in electrical laminates, base for synthetic turf; typical uses for bitumen 150/5 include roofing, pipe coating, hydraulic applications, 150/5 is mainly using in paint manufacturing and coating in hot area. It’s used as raw material for bitumen coats, roofing, and insulation also in the Isolation bitumen membrane sheet. Also Oxidized asphalt 150-5 uses in chemical, fuel, paints, lacquers, varnishes, paper-pulp-board, and textile processing. In road construction, pavement, crack seal and repairmen, civil works, roofing also construction. In addition, it uses for sealing and insulating buildings, adhesive, construction materials additive, dust-binding, and coating. With a wide range of uses in insulating and impregnating agents, make rubber and plastic products. The blown asphalt 150-5 products are for paving, and roofing. Also used in asphalt-based paints for corrosion protection of metals, inlining public works structures, adhesives in electrical laminates, and base for synthetic turf. Typical uses for Oxidized Bitumen 150/5 also include roofing, pipe coating, Portland cement pavement, hydraulic applications, and paint manufacturing.

APPLIATION OF OXIDIZED BITUMEN 150/5

Oxidized Bitumen 150/5, also known as R150/5 blown bitumen, has increased rubber properties compared to lower grades because to its unique oxidation process. As a result of these features, it has a wide range of potential commercial uses. Roofing, facing, flooring, undercarriage sealant in the automotive industry, pilling, electrical operations, cable coating, oil and gas pipelines coating, crack sealing, road repair operations, pulp papers, bituminous products, textiles, joint filling compound, sound-reducing agent, dust proofing, waterproofing, lacquers, and many other products all benefit from its use. It is also utilized as a component in hydraulic applications and operations, Portland cement pavements, as a basis for synthetic grass, the manufacturing of rubber and plastic, and as an adhesive, insulator, and isolation bitumen membrane sheet. Oxidized Grade Bitumen shall be broken up into small pieces and heated slowly to the application temperature of 220ºC to 230ºC.

PERFORMANCE CHARACTERISTICS IN HIGH-TEMPERATURE CLIMATES

Oxidized Bitumen 150/5 shows exceptional performance in tropical and desert climates (e.g., Gulf, Africa), resisting deformation under high pavement temperatures (>70°C). Include comparative data: 30–40% better flow resistance than standard paving bitumen 60/70.

COMPATIBILITY WITH POLYMERS AND ADDITIVES

150/5 can be blended with SBS, APP, or EVA polymers to produce modified bitumen membranes with superior elasticity and crack resistance.

Applications: Waterproofing membranes, expansion joint sealing, bridge deck coating.

ENVIRONMENTAL AND SUSTAINABILITY ASPECTS

Modern production emphasizes low-emission oxidation reactors and the use of recycled bituminous feedstocks, reducing CO₂ emissions.

Extra point: Blown bitumen residues can be reused in insulation boards or as fuel substitutes, minimizing waste.

MARKET OVERVIEW AND GLOBAL DEMAND

Demand for Oxidized Bitumen 150/5 is growing in Asia-Pacific, Africa, and the Middle East, especially for waterproofing and pipe coating applications.

Trend Insight: Due to urbanization, the waterproofing segment accounts for 35–40% of total demand.

QUALITY CONTROL AND TESTING BEYOND ASTM

In addition to ASTM D36 and D5, other relevant standards include:

- EN 1426 / EN 1427 – European penetration and softening tests

- ISO 4625 – Ring and Ball softening point

- FTIR spectroscopy – to monitor oxidation level and functional group formation

HANDLING AND TRANSPORTATION INNOVATIONS

Meltable polyethylene (PE) bags and jumbo-bag systems reduce manual handling risks and environmental impact from steel drums.

New Packaging Sizes: 1 MT meltable jumbo bags are replacing 200 kg drums for easier bulk handling and lower logistics costs.

EXTENDED APPLICATIONS

- Not mentioned in original post:

- Solar panel waterproof coatings (UV-resistant membranes)

- Bitumen-based mastics for ship decks and ports

- Industrial floor coating for chemical resistance

- Acoustic insulation panels in prefabricated buildings

- Joint sealing compounds for airport runways and bridges

STORAGE STABILITY AND SHELF LIFE

When stored below 50°C and protected from moisture, Oxidized Bitumen 150/5 maintains stable physical properties for over 24 months, ensuring long-term usability.

SAFETY AND ENVIRONMENTAL PRECAUTIONS (UPDATED MSDS INSIGHT)

- Use of infrared thermometers for real-time monitoring during melting to prevent overheating.

- Avoid open-flame heating; adopt indirect hot-oil systems.

- Provide local ventilation systems to manage fumes during use.

SURFACE PREPARATION

Before using Oxidized bitumen 150/5 surfaces must be dry, clean, and free of loose types, curing products, disorders, and slurry. Furthermore, if you use this type of bitumen without cleaning the area bitumen 150/5 will easily remove.

OXIDIZED BITUMEN 150/5 USING WAY

For using Blown bitumen 150/5 first it must heat to about 300 °C for melting and using in different industries because it is hard bitumen and breakable. Oxidized Bitumen 150/5, also known as blown or air-blown bitumen, is a type of bitumen that has been subjected to an oxidation process. This process increases its softening point and enhances its properties.

HERE ARE SOME COMMON WAYS IN WHICH OXIDIZED BITUMEN 150/5 IS USED:

- Roofing and Waterproofing: One of the primary applications of Oxidized Bitumen 150/5 is in roofing and waterproofing. It is used in the manufacture of roofing membranes, roofing felts, and waterproofing materials. The oxidized bitumen forms a durable and weather-resistant layer, providing protection against moisture.

- Asphalt Pavement Construction: Oxidized bitumen is sometimes used in asphalt mixes for road construction. It can contribute to the durability and stability of asphalt pavements. However, the specific grade and application may vary based on regional specifications.

- Pipe Coating: In the oil and gas industry, Oxidized Bitumen 150/5 is used as a coating for pipes. The oxidized bitumen provides corrosion resistance and insulation to protect pipes from environmental factors.

- Joint Fillers: Oxidized bitumen is used as a component in joint fillers for construction purposes. It helps seal joints and gaps in structures, providing flexibility and preventing water penetration.

- Soundproofing Applications: Oxidized bitumen may be used in soundproofing materials for buildings and infrastructure. Its ability to absorb sound contributes to reducing noise transmission.

- Adhesives and Sealants: Oxidized Bitumen 150/5 is employed in the manufacturing of adhesives and sealants. It acts as a binder, providing adhesion and sealing properties in various industrial applications.

- Paints and Coatings: Some formulations of paints and coatings may include oxidized bitumen to enhance their properties, such as weather resistance and durability.

- Cable Coating: Oxidized bitumen is used as a coating for cables, providing insulation and protection against environmental elements.

It’s essential to follow recommended guidelines and specifications for the specific application of Oxidized Bitumen 150/5. The choice of application depends on factors such as climate conditions, project requirements, and regional standards. Manufacturers and suppliers typically provide technical data and usage recommendations for their specific products.

TECHNICAL ADVANTAGES OF OXIDIZED BITUMEN 150/5

- Durability

- Flexibility

- Water-Resistant

- Chemical Stability

COMPARED TO PAVING GRADE BITUMEN:

- Reduced temperature susceptibility

- Exhibits a more ‘solid’ nature at ambient temperatures

- High penetration index

STORAGE AND HANDLING

Heating of packaged bitumen is a critical phase in most of the final uses. Typically, the packaged material is heated and melted in boilers out on site. However, control at the heating phase is very important in terms of health and safety as well as in maintaining the quality of the product.

Note must be taken of the maximum safe handling temperature of 230 C and this should not be abused. Bitumen is a poor conductor of heat, consequently, control of the heating phase is of paramount importance. The Oxidized Bitumen material should be broken up prior to placement in the boiler. This exposes a larger surface area to the heat and encourages a more even heating regime. Without the larger exposed surface area, aggressive heating at the base and sides of the boiler may well result in localized overheating, altering the characteristics of the RAHA OIL modified bitumen and potentially causing thermal cracking of the bitumen, creating the release of low lash vapors. The flash point of the oxidized bitumen then becomes irrelevant; as these low flash vapors determine the fire risk. Melted bitumen should not be left in the boiler and reheated from cold, as there is then a high potential for localized overheating around the heating area (lack of convection means poor heat transfer) and potential development of a pressurized pocket of low flash vapors. Be aware of the placement of any temperature monitoring or control devices. As a result of the poor thermal conductivity of the bitumen, a thermometer in the bitumen some distance from the heat source could read significantly different (even hundreds of degrees) from the true temperature of the bitumen near the heat source. For Health and Safety information, please make reference to the relevant MSDS.

HEALTH & SAFETY OF OXIDIZED BITUMEN 150/5

Workers should wear protective masks, gloves, and goggles during application. The asphalt can be removed from equipment and tools with kerosene or gasoline. Care should be taken when heating oxidized Bitumen 150/5 to avoid over heating.

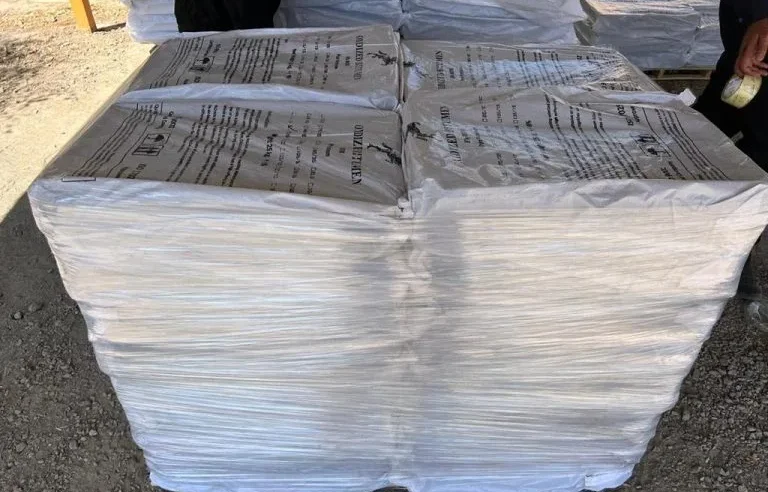

PACKING OF BLOWN ASHALT 150/5

Oxidized Bitumen 150/5 Packing

TECHNICAL DATA SHEET OF OXIDIZED BITUMEN 150/5

BITUMEN 150/5 TEST METHOD UNIT SPECIFICATION

Specific gravity @ 25/25 °c ASTM D70 Kg/cm³ 1.05 approx

Penetration @ 25°c ASTM D5 mm/10 4-6

Softening point °c ASTM D36 °C 145-155

Ductility @ 25°c ASTM D113 cm 145-155

Loss on heating(wt) % ASTM D6 wt % 0.2 max

Flashpoint °c ASTM D92 °C 250 min

Solubility is CS2(wt) % ASTM D4 wt % 99.5 max

Spot test A.a.s.h.o.t102 wt % Negative

For more information, please Contact our Sales Team.