Wax

Wax

WAX TYPES

RAHA Group UAE branch can provide different grades of waxes that derive from petroleum. There are various types of waxes used for different purposes.

SOME COMMON TYPES INCLUDE:

- Paraffin Wax: Derived from petroleum, it’s often used in candles, cosmetics, and for sealing jars.

- Slack Wax: Derived from petroleum, it is used as raw material for making paraffin wax, candle, petroleum jelly

- Polyethylene Wax: Synthetic wax used in a variety of applications, including as a lubricant and in the production of certain types of polishes.

- Microcrystalline Wax: A byproduct of petroleum refining, used in various industries including cosmetics, pharmaceuticals, and food.

- Residue Wax (Foots oil): it is residual wax from paraffin wax production process.

- Beeswax: Natural wax produced by bees. It’s used in candles, skincare products, and as a coating for certain foods.

- Soy Wax: Made from soybeans, it’s a popular choice for environmentally conscious candle makers.

- Carnauba Wax: Derived from palm leaves, it’s often used in car waxes, shoe polishes, and as a coating for some candies.

- Shellac Wax: Obtained from the lac insect, it’s used in wood finishes and some food glazes.

These waxes have diverse properties that make them suitable for different purposes. In the below we introduce some of these waxes in summary.

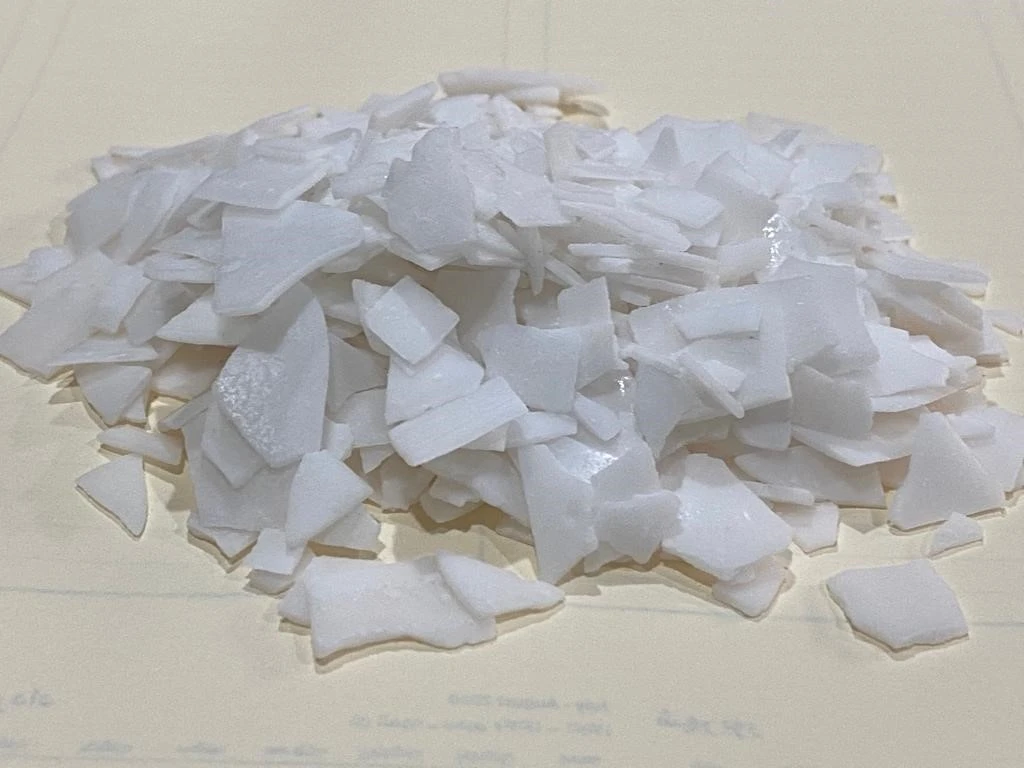

PARAFFIN WAX

Paraffin wax

Paraffin wax

Paraffin wax is a white or colorless soft solid derivable from petroleum, coal or oil shale, that consists of a mixture of hydrocarbon molecules containing between twenty and forty carbon atoms.

THESE WAXES ARE CATEGORIZED BY OIL CONTENT AND THE DEGREE OF REFINEMENT.

- The crudest versions fall into the slack wax category and contain between 7% to 20% oil.

- Next on the step of refinement are scale waxes containing between 0.5% to 7% oil that are called Semi Refined Paraffin Wax.

- The highest grade of refinement is the Fully Refined Paraffin Wax that has maximum 0.5% oil.

Paraffin wax, colorless or white, somewhat translucent, hard wax consisting of a mixture of solid straight-chain hydrocarbons ranging in melting point from about 52° to 66° C (120° to 150° F).

SLACK WAX

Slack Wax

Slack Wax

Slack Wax is a petrochemical product of refineries so this is highly related to oil in refinery towers wax is near to bitumen and their difference is in the color. Bitumen is quite black but wax is dark to light brown. First product of refinery is slack wax which can be heavy or light according to its carbon chain and chemical elements. Slack wax was considered as rubbish 50 years ago and refineries paid extra cost to send slack wax to the suburb to be unloaded and vanished there but now it is a very famous and useful petrochemical product.Slack wax is processed by DE-oiling and DE-coloring in factories the end product is paraffin wax depending the process we will have fully refined and semi refined paraffin wax from 0.5% to 7% oil content. What remains of extracting oil from slack wax and producing paraffin wax is residue wax or foots oil even this product has a role in industries nowadays.

slack wax has also some grades based on oil content 5% to 35% and melting point 50 °C to 55 °C, its color differs from yellow to brown, slack wax light and heavy is used mainly for paraffin wax manufacturing, matches industry.

POLYETHYLENE WAX

Polyethylene Wax

Polyethylene Wax

Polyethylene Wax, also known as PE Wax, is an ultra-low molecular weight polyethylene consisting of ethylene monomer chains. PE wax has a large variety of uses and applications. PE Wax is available from on-purpose production and as a byproduct of polyethylene production. This material is available in both HDPE and LDPE forms. As there are many grades and types available, please inquire so that one of our knowledgeable representatives can assist you in locating the correct grade that matches your requirements.

There are a variety of methods for producing Polyethylene wax. Polyethylene wax can be made by direct polymerization of ethylene under special conditions that control molecular weight. Another method involves breaking down high molecular weight polyethylene into lower molecular weight fractions. A third method involves separation of the low molecular weight fraction from high molecular weight polymer.

RESIDUE WAX

Foots oil or residue wax

Foots oil or residue wax

Foots oil or residue wax, is a byproduct obtained by slack wax de-oiling or sweating in the paraffin wax manufacturing process. It is used in textile, leather and rubber industries, as well as petroleum jelly and white oil manufacturing. Residue wax is the mixture of oil and slack wax. This wax, formally known as Foots oil is a commodity derived from the production of semi refined paraffin wax, having almost 60% result from 100% of slacks provided by the oil refineries.

FOOTS OIL IS USED IN THE FOLLOWING PRODUCTS:

Adhesives and sealants, anti-freeze products, coating products, fillers, putties, plasters, modelling clay, finger paints, fertilizers, fuels, non-metal-surface treatment products, inks and toners, leather treatment products, lubricants and greases, plant protection products, polishes and waxes and textile treatment products and dyes.

Other release to the environment of this substance is likely to occur from: indoor use as processing aid, outdoor use as processing aid, indoor use in close systems with minimal release (e.g., cooling liquids in refrigerators, oil-based electric heaters) and outdoor use in close systems with minimal release (e.g., hydraulic liquids in automotive suspension, lubricants in motor oil and break fluids).

For more information, please Contact our Sales Team.