Alkyd Resin

Alkyd Resin

WHAT IS ALKYD RESIN?

Alkyd resin is one of the most widely used resins in the paint industry (solvent-based paints). The final properties of this resin depend on the type of raw materials used in the reaction.

HOW MANY CATEGORIES ARE ALKYD RESINS DIVIDED INTO?

As previously stated, an oil base is required to prepare alkyd resin. The amount or percentage of oil used, also known as oil length, determines the properties of the resin and its classification is made on this basis. These types of resins are classified into three groups of alkyds with long, medium and short oil lengths.

ALKYD RESIN WITH LONG OIL LENGTH

High gloss and gloss retention, good drying. Decorative enamel for interior & exterior applications. High viscosity resin for good pigment wetting. If the amount of oil used in the alkyd resin is high (55 to 60% by weight and 20 to 30% anhydrous phthalic), the resin will exhibit more oily properties. These properties include:

- High solubility in aliphatic solvents such as white spirit

- Better brushability (easy to apply with a brush and roller)

- Lower hardness

- Greater flexibility

- Low viscosity

- Slow drying speed

- Relatively resistant to moisture and sunlight

This type of alkyd resin is mostly used in the production of construction oil paints.

APPLICATION

Good color and gloss retention, good drying, decorative enamel for interior and exterior applications. High viscosity resin for good pigment wetting.

SHORT OIL ALKYD RESIN

If the amount of oil used is low (between 25 and 44% by weight and more than 34% phthalic anhydride), alkyd resin exhibits polyester properties. These properties include:

- Solubility in aromatic solvents such as toluene and xylene

- Poor scratch resistance (applied by spray)

- Higher hardness

- Less flexibility

- High viscosity

- Fast drying speed

- Low impact resistance

- Higher durability

This type of alkyd resin is mostly used in the production of industrial paints (baking paints and primer paints).

MEDIUM OIL ALKYD RESIN

High gloss and gloss retention, good drying. Decorative enamel for interior & exterior applications. High viscosity resin for good pigment wetting. The amount of oil used in these resins is medium (between 45 and 55 percent by weight and 30 to 35 percent phthalic anhydride) and therefore they will have both oil and polyester properties. In such a way that by playing with the percentages, alkyds can be produced that have both industrial and construction applications.

Medium oil alkyds, due to their improved properties and having a higher percentage of polyester properties, have been more considered in terms of application than the long oil type in construction paint applications because the polyester properties cause them to show higher resistance to corrosion.

They are also used in the production of automotive oil paints due to their higher resistance to ultraviolet radiation.

APPLICATION

Architectural undercoats, general purpose white and dark shade enamels, primers for auto refinish.

TYPES OF OILS USED IN THE PRODUCTION OF ALKYD RESIN

- Castor oil

- Coconut oil

- Soybean oil

- Cottonseed oil

- Tall oil

- Bazrak oil

- Tang oil

Using oils instead of fatty acids is more economical, and the resulting resin will have greater solubility in aliphatic solvents. Resins produced from fatty acids have a brighter color and higher chemical resistance due to the higher purity of the fatty acid, but at the same time the cost of resin production in these cases is higher and there are problems such as fatty acid corrosion and container rust.

TYPES OF POLYOLS IN ALKYD RESIN PRODUCTION

- Glycerin

- Pentaerythritol

- Trimethylolpropane

- Glycol

- Sorbitol

WHAT ARE POLYOLS?

Alcohols with more than two hydroxyl (OH) groups are called polyols. Glycerin, pentaerythritol, and sorbitol are the most important polyols used to produce alkyd resins.

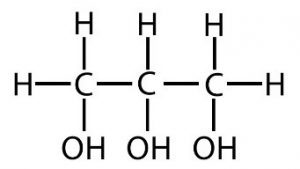

GLYCERIN

Glycerin is a highly viscous liquid, the industrial form of which is called glycerol. This alcohol is the main polyol in the manufacture of alkyd resins, which has a functionality of less than three due to the presence of one –OH group in the middle of the molecule despite the presence of three hydroxyl groups.

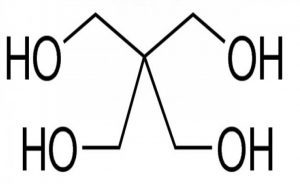

PENTAERYTHRITOL

It has four hydroxyl groups (-OH), meaning it is tetrafunctional, which is second only to glycerin in importance, and has three commercial forms: monopenta, dipenta, and tripenta. In fact, monopenta is used more than its other relatives.

It is interesting to know that in most cases, pentaerythritol is used together with glycerin and ethyl glycol to reduce the risk of gelling and increase the solubility of the resin.

The following are some of the positive features of pentaerythritol:

- Increasing the viscosity of the resin

- Shortening the drying time

- Greater resistance to yellowing and heat

- Higher brushability

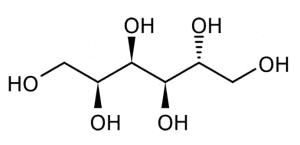

SORBITOL

With six hydroxyl groups, it has a functionality of three, due to the loss of a water molecule and the formation of an ether bond. Like glycerin, it has a high viscosity and is dehydrated at the esterification temperature of the alkyd. It is used in small amounts with pentaerythritol.

TYPES OF ANHYDRIDES IN ALKYD PRODUCTION

- Phthalic Anhydride

- Maleic Anhydride

- Benzoic Acid

- Trimellitic Anhydride

WHAT ARE ANHYDRIDES?

Acid anhydride is an organic compound that has two bonds from the acyl group attached to the same oxygen atom. Phthalic anhydride, maleic anhydride are among the most important anhydrides in the production of alkyds. The more linear and simpler the monomer, the more flexible the resin will be.

ADVANTAGES OF USING ALKYD RESINS

- Cheap price

- Solubility in chemical solvents

- Compatible with other resins

- Easy resin preparation process

TYPES OF ALKYD RESINS BASED ON THE TYPE OF DRYING

Alkyd resins are divided into two drying groups: 1- in contact with free oxygen (with low hydroxyl) and 2- oven (with high hydroxyl).

DIFFERENCE BETWEEN POLYESTER RESIN AND ALKYD RESIN

Polyester resin is hard and brittle, but the presence of oil or fatty acid in the alkyd resin chain improves the flexibility and durability of the paint, its wetting properties and adhesion strength to the surface, and slows down the drying time.

TECHNICAL DATA SHEET OF LONG OIL ALKYD RESINS

Products % NVM

(Volatile/

solvent)Acid value

(mg KOH/

gm)Color

Gardner

(@% Solids)Viscosity B4

F/C @30°C

(@% Solids)Viscosity

Gardner

@25°C

(as such)Oil Type %Oil

(approx)%PA

(approx)

Description / Uses

S 10001 95.0 min

15.0 max 5.0 max

(as such)20.0-25.0 Sec

(70.0%)U – Y Fatty

acid60.0 25.0 Decorative enamel for interior and exterior

applications. High solid resin for good

pigment wetting.

S 10951WS 95.0+/- 1.0

(WS)10.0 max 4.0 max

(50.0%)180.0- 220.0 Sec

(50.0%)- Veg. oil /

Fatty acid60.0 25.0 High solids for decorative enamel for interior

and exterior applications.

S 10801WS 80.0+/- 1.0

(WS)12.0 max 4.0 max

(50.0%)140.0-160.0 Sec

(50.0%)Z7 +/- Veg. oil /

Fatty acid60.0 25.0 Good color and gloss retention, good drying,

decorative enamel for interior and exterior

applications. High viscosity resin for good

pigment wetting.

S 10701WS 70.0+/- 1.0

(WS)10.0 max 4.0 max

(50.0%)130.0-150.0 Sec

(50.0%)Z6 +/-

Veg. oil /

Fatty acid60.0 25.0 Good color and gloss retention, good drying.

Decorative enamel for interior and exterior

applications.

S 10701HVWS 70.0+/- 1.0

(WS)

10.0 max 4.0 max

(50.0%)100.0-130.0 Sec

(45.0%)Z7 Veg. oil /

Fatty acid60.0 25.0 High viscosity and rest of the properties as

per S 10701WS.

S 10702WS 70.0+/- 1.0

(WS)10.0 max 4.0 max

(50.0%)180.0- 220.0 Sec

(50.0%)Z7 – Z8 Veg. oil /

Fatty acid60.0 25.0 Good color and gloss retention, good drying.

Decorative enamel for interior and exterior

applications.

S 10702HVWS 70.0+/- 1.0

(WS)12.0 Max 4.0 max

(50.0%)Z1 - Z2

(50.0%)Z9 +

Veg. oil /

Fatty acid60.0 25.0 High viscosity and rest of the properties same

as S 10702WS.

S 10703JWS 70.0+/- 1.0

(WS)10.0 max 4.0 max

(50.0%)200.0-220.0 Sec

(50.0%)Z9 +/-

Veg. oil /

Fatty acid60.0 25.0 Good color and gloss retention, good drying.

Decorative enamel for interior and exterior

applications.

S 10703WS 70.0+/- 1.0

(WS)

10.0 max 4.0 max

(50.0%)230.0-250.0 Sec

(50.0%)Z9 +/- Veg. oil /

Fatty acid60.0 25.0 Good color and gloss retention, good drying.

Decorative enamel for interior and exterior

applications.

S 10704WS 70.0+/- 1.0

(WS)12.0 max 4.0 max

(50.0%)250.0-280.0 Sec

(50.0%)Z9 +/-

Veg. oil /

Fatty acid60.0 25.0 Good color and gloss retention, good drying.

Decorative enamel for interior and exterior

applications.

S 10708WS

70.0+/- 1.0

(WS)10.0 Max 3.5 max

(40%)V - X (40%)

25⁰C- Veg. oil /

Fatty acid60.0 25.0 Very high viscosity. Good color and gloss

retention, good drying. Decorative enamel for

interior and exterior applications.

S 10702NY 60.0+/- 1.0

(WS)13.0 max 5.0 max

(as such)P - S

25⁰CZ3 – Z5 Veg. oil /

Fatty acid60.0 25.0 Non yellowing, good color and gloss retention,

good drying. Decorative enamel for interior

and exterior applications.

S 10551WS

55.0+/- 1.0

(WS)12.0 max 4.0 max

(50.0%)75.0-95.0 Sec

(50.0%)T - W Veg. oil /

Fatty acid60.0 25.0 Good color and gloss retention, good drying.

Decorative enamel for interior and exterior

applications. Primers for metal and wood

interior & exterior finishes.

S 10552WS 55.0+/-1.0

(WS)7.0 max 4.0 max

(50.0%)200.0 - 220.0 Sec

(50 %)Z1 - Z2 Veg. oil /

Fatty acid60.0 25.0 High viscosity and rest of the properties same

as S 10551WS.

TECHNICAL DATA SHEET OF MEDIUM OIL ALKYD RESIN

Products

% NVM

(Volatile/

solvent)

Acid value

(mg KOH/

gm)Color

Gardner

(@% Solids)Viscosity B4

F/C @30°C

(@% Solids)Viscosity

Gardner

@25°C

(as such)Oil Type %Oil

(approx)

%PA

(approx)Description / Uses

S 20502WS 50.0+/- 1.0

(WS)15.0 max 4.0 max

(40.0%)220.0- 240.0 Sec

(40.0%)Z4 – Z6 Veg. oil /

Fatty acid

50.0 35.0 Architectural undercoats, general purpose

white and dark shade enamels, primers for

auto refinish.

S 20505WS 50.0+/-1.0

(WS)12.0 Max

4.0 max

(40.0%)200.0- 240.0 Sec

(40.0%)X - Y

(@ 40%

Solid )Veg. oil /

Fatty acid

50.0 35.0 Fast drying for architectural undercoats,

general purpose white and dark shade

enamels.

S 20552WS

55.0+/- 1.0

(WS)

15.0 max 4.0 max

(40.0%)90.0-120.0 Sec

(40.0%)Z6 – Z8 Veg. oil /

Fatty acid

50.0 35.0 Architectural undercoats, general purpose

white and colored enamels, fast drying,

auto refinish.

S 20601WS

60.0+/- 1.0

(WS)10.0 max 4.0 max

(40.0%)90.0-130.0 Sec

(40.0%)Z – Z1 Veg. oil /

Fatty acid

50.0 35.0 Architectural undercoats, general purpose

white and dark shade enamels, fast drying

auto refinish.

S 20601XL 60.0+/- 1.0

(Xylene)

10.0 max 4.0 max

(50.0%)90.0-160.0 Sec

(50.0%)Z3 – Z4 Veg. oil /

Fatty acid

50.0 35.0 Architectural undercoats, general purpose

white and dark shade enamels, fast drying

auto refinish

S 20701XL 70.0+/- 1.0

(Xylene)15.0 max 4.0 max

(50.0%)90.0-160.0 Sec

(50.0%)Z5 – Z6 Veg. oil /

Fatty acid

50.0 35.0 Architectural undercoats, general purpose

white and dark shade enamels

For more information, please Contact our Sales Team.